News & Events | Page 4 of 8 | Hetech

Yesterday, 4th May Queensland’s Space sector came together to discuss the future of Space in QLD. It was a great event to get the industry together and network with our peers, fostering future collaborations and partnerships.

Mark Steiner attended the event, “Hetech supplies printed circuit boards to Gilmour Space so we are invested and excited about the future of Space in QLD. The event was incredibly interesting with Boeing presenting a path to a successful Mars landing in the years to come!”

At the event, we heard from some great speakers including, Michael Elsperman, Director of Space Exploration (Boeing USA) who spoke about NASA’s Artemis mission to establish a long-term human presence on the moon.

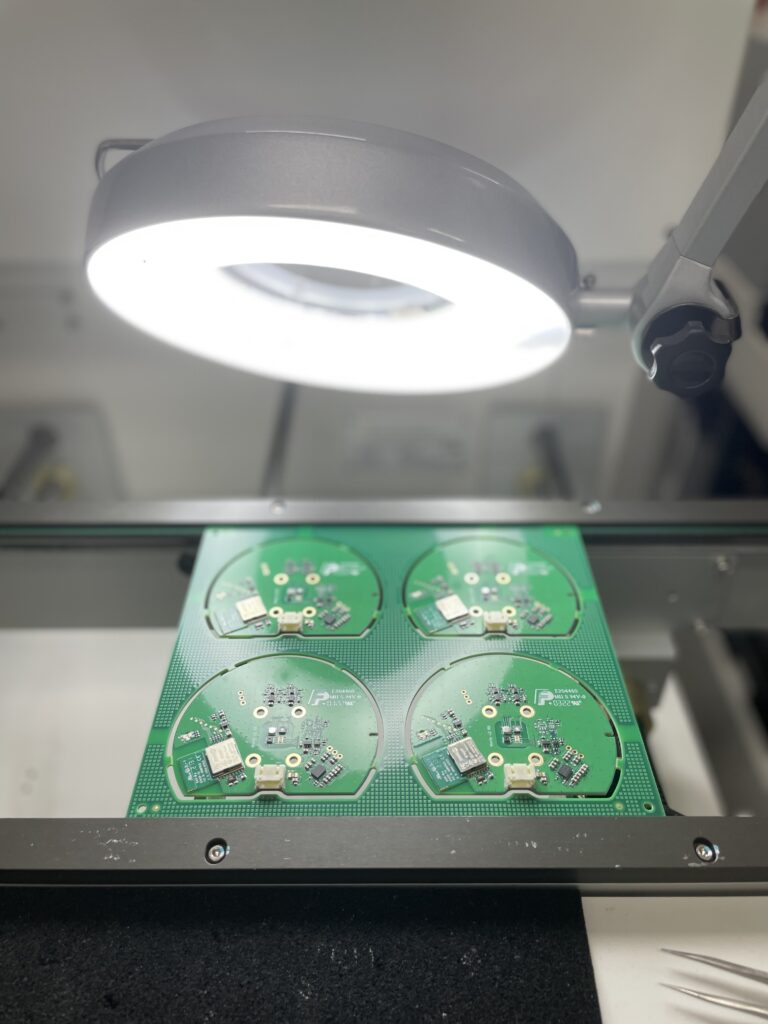

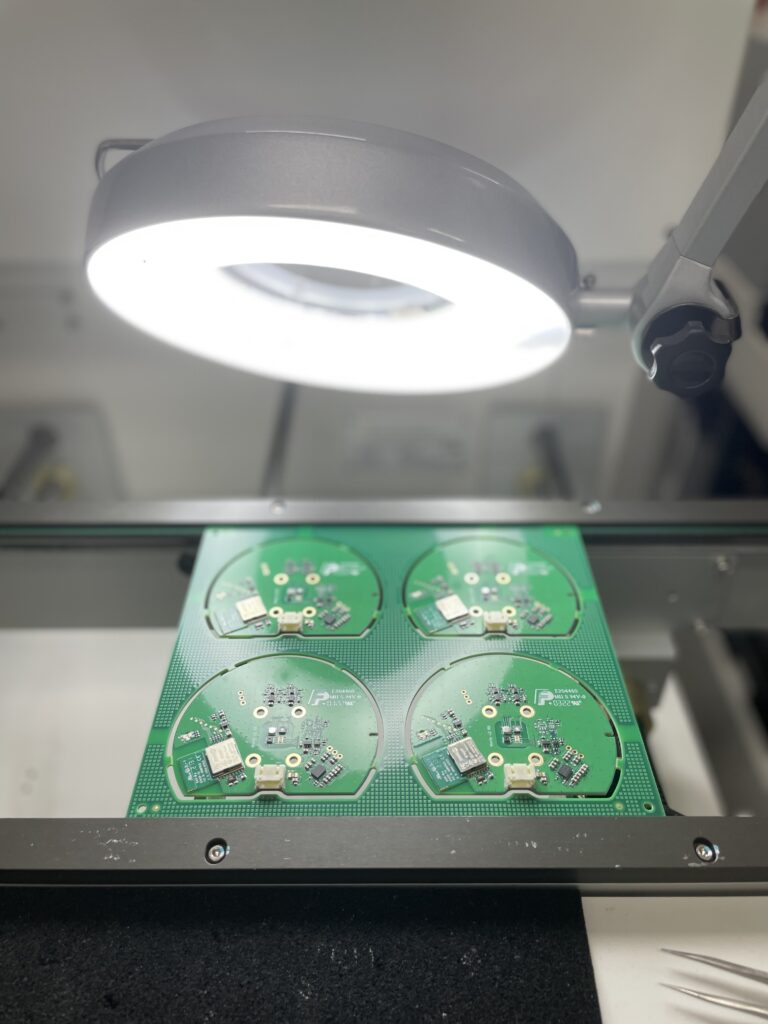

As electronic design and manufacturing experts, we have the relevant skills and experience to deliver high-quality PCB assembly services. Our machine room contains the latest technology, is fully ESD compliant and is able to handle PCB assembly projects of all sizes. Our fully automated component feeding, wave soldering and automated inspection ensure every project we complete meets our high standards.

What is SMT?

SMT is the method of mounting components onto circuit boards directly, rather than soldering between two points on a circuit board, known as through-hole. SMT was developed to use PCB space more efficiently and lower production costs, which is why the method is still popular today. Compared to other assembly methods, this process is generally considered more accurate due to its high level of automation.

What are the benefits of SMT?

• Size: With SMT, components are smaller in size so more can be fitted onto the board compared to the through-hole assembly process. As the board can be reduced in size, its weight is similarly reduced to 1/10th compared to through-hole assembly.

• Cost: PCB manufacturing costs can be reduced as fewer holes are required reducing the amount of drilling required on the circuit board.

• Speed: The SMT process can be completed at a much quicker and controlled rate. Every step in the process from component placement to inspection can be automated, preventing human error and creating faster results.

After a 2 year hiatus, Indo Pacific is back at the International Convention Centre, Sydney.

Hetech Will Showcase Its Electronics Design & Manufacturing Capabilities

It’s been a while since we’ve been able to meet with our different industry partners and colleagues but we know this year will be better than ever.

As in 2019, Hetech will again be exhibiting on the QLD Government stand, make sure to stop by and say Hi!

Or, if you’d like to schedule a meeting simply contact us via the link below.

International Maritime Exposition is your gateway to an Australian and regional marketplace with dynamic fleet acquisition and equipment programs underway.

INDO PACIFIC 2022 will be the 12th iteration of this internationally renowned event, which in 2019 attracted:

- 657 participating exhibitor companies from 22 nations

- 182 industry, government, defence and scientific delegations from 48 nations, including 45 international naval delegations and 21 Chief of Navy counterparts from across the region

- 48 major conferences, symposia and forums

- 21,241 attendances across three days.

INDO PACIFIC 2022 is where customer and industry will connect, where commercial maritime and naval defence suppliers will promote their capabilities to decision-makers from around the world, in the only maritime exposition of its kind in the Indo Pacific region.

As the signature maritime event for the region, INDO PACIFIC 2022 offers an unparalleled concentration of:

- Defence and Civil decision-makers

- Tier 1 and Tier 2 suppliers

- Small to Medium Businesses

- Prime Contractors

- Universities and Research Organisations

INDO PACIFIC 2022 is the prime face-to-face event for:

- Direct Sales

- Business Development

- Product Launches

- Relationship Development

- Market Research

- Supply Chain Development

It was great to be back exhibiting at Electronex this year.

Along with a number of great exhibitors, Electronex also held several free seminars providing up to date information about the electronics landscape in Australia today.

The competitive future of practically every Australian industry sector is increasingly dependent on the utilization and integration of the latest electronics into all aspects of manufacturing, production, assembly, systems development, maintenance and service.

At Electronex designers, managers, engineers, technicians, manufacturers and system integrators discussed their specific requirements with our industry experts. Contact us if you’d like to discuss your requirements.

A great event in Sydney today, our Managing Director, Mark Steiner attended the Australian Space Summit.

Australia’s space sector has an incredibly exciting future as it continues to transform and grow into a globally respected space industry.

The Australian Space Summit offered the opportunity to engage and hear directly from the space experts and industry professionals that are committed to evolving Australia’s space industry.

This event delivered relevant insights and market intelligence to help better shape business decisions and will provide topical information for the full breadth of the space sector.

- Monty Compost is an innovative compost tool used to manage your compost efficiently and effectively.

- World-first compost monitoring device and mobile app that work together to track your compost’s health, gamify your decomposition data and engage with your organics.

- Hetech manufacture the PCBA’s for Monty Compost.

At Hetech, we work with customers who are both established and at the beginning of their life cycle, recently we started working with Ash Baxter on her product Monty, an innovative composting companion.

Ash is the true definition of an entrepreneur, coming up with her business idea in her last year of university at UQ, a local Brisbane university. After months of research, Ash came up with the idea of a tool to optimise the composting process which was then accepted into the ilab Accelerator program and received seed funding to take her business to the next level.

Hetech were approached by Monty Compost and Carbon Circuits to manufacture the PCBA’s (Printed Circuit Board Assemblies) for the product.

Hetech prides itself on being an expert Australian PCB manufacturing & assembly company that supplies PCB assembly solutions to businesses of all sizes across Australia.

Monty Compost Co is an innovative and intelligent environmental compost solution that aims to help make composting easy and efficient for everyone through the power of technology.

Monty takes out the composting learning curve, put Monty into your compost and it will tell you exactly what it needs through an app. Some great examples of the product in use are – Your compost needs to be turned. Your compost needs more waste. Composting made smarter, better and faster with our world-first compost monitoring device and mobile app that work together to track your compost’s health, gamify your decomposition data and engage with your organics.

The vision of the company is a world where 100% of our organic waste is recycled back into our soil. They believe that compost can be a big part of this and are working to enable anyone to do it.

Ash said of her recent visit to Hetech HQ:

“As an Australian, and specifically Queensland, founded company, it was such an amazing experience seeing Monty being made in Queensland by Queenslanders.

After three years working on Monty through countless prototype and MVP iterations, having this level of production around it is wild.

It was even better being able to share it with the team and meet in person the people helping make Monty happen.“

It’s been a tough few years of component shortages and unfortunately, this doesn’t look to change for the rest of 2022 with shortages forecasted to continue throughout the rest of the year.

Supply chains to improve in late 2022

A report, titled “Tech, Media, and Telecoms Predictions 2022,” details that the conflict between the US and China over the supply chain of chips and minerals will remain heated for most of this year but will begin to improve in the latter half of 2022. Daniel Clarke, an analyst on the Thematic Research Team has said that consumers could expect the automotive and tech industries to be the most impacted. You can read the full Deloitte report here.

Rise of onshoring

Over the past year, we have also seen a trend of Australian businesses bringing their electronic manufacturing back to Aussie shores. This trend has been brought on by continued international conflict, component shortages and a lack of control over IP/process, redundancy. According to research published by the Advanced Manufacturing Growth Centre last year, more and more Australians are valuing the industry, and 72 per cent of Australians see it as important or very important, up 7 per cent between 2019 and 2021.

Government-backed industry

Brent Balinski from Australian Manufacturing was quoted saying, ‘We predict manufacturing and its role in sovereignty will be a 2022 election issue, with the investment in the industry by the federal government and the effectiveness of this and other industrial policies certain to be debated.’ Read more here.

At Hetech, we have been working with local businesses to bring their electronic manufacturing back to Australian shores and, sourcing components for our customers at a time when the world is seeing delays and shortages.

We have partnered with a range of companies such as CSIRO, Boeing Defence, Saab, WEIR, BV and FLSmidth on projects to reduce costs and integrate automation. We are also involved in a vast range of other projects for industries such as Mining, Renewables, Defence, Utilities and many more. Working with IoT/sensor solutions, PCB builds, insourcing, redesigning & designing electronics equipment for more efficient solutions.

After a two year hiatus, we are happy to see Electronex is back for 2022!

Data and Time

Tues, 5th April: 10.00 am – 6.00 pm

Wed, 6th April: 9.00 am – 4.00 pm

Location

Rosehill Gardens – James Ruse Dr, Rosehill, NSW, 2142, Sydney FREE PARKING.

At Electronex designers, managers, engineers, technicians, manufacturers and system integrators can discuss their specific requirements with industry experts and see, test and compare the latest products and solutions to help them in their business.

As a leading electronic parts supplier and manufacturer, Hetech is excited to announce our participation in this year’s Electronex expo.

During the exhibition, we’ll be located at Stand C24. Over the years we have worked with hundreds of clients throughout Australia and, our team would love to discuss how we can partner with your company to improve your bottom line and capabilities.

Can’t make it to the exhibition? Feel free to contact us via email: carcher@hetech.com.au, phone: 07 3297 9700

EcoJoule’s EcoVAR helping grid businesses towards a net-zero future

Quick facts on the EcoVAR

- EcoJoule is improving and innovating electricity supply through smart grid technology.

- The influx of solar on homes and businesses changes the way the local grid operates. EcoVAR technology helps improve voltages and increases the ability of solar to export clean energy.

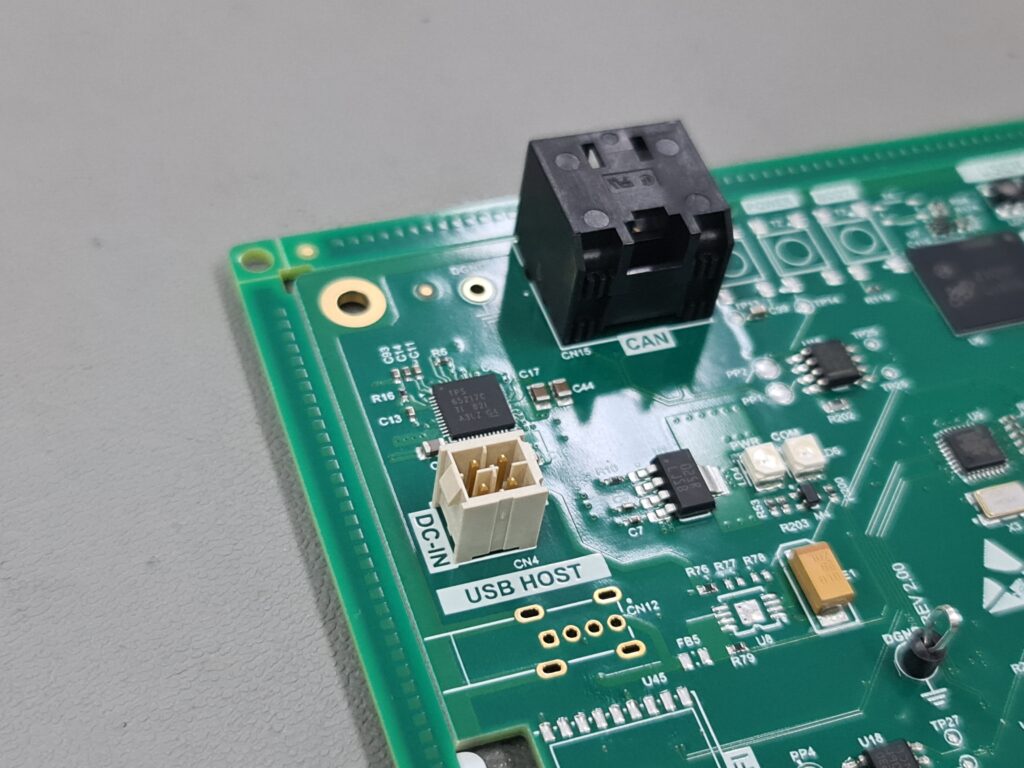

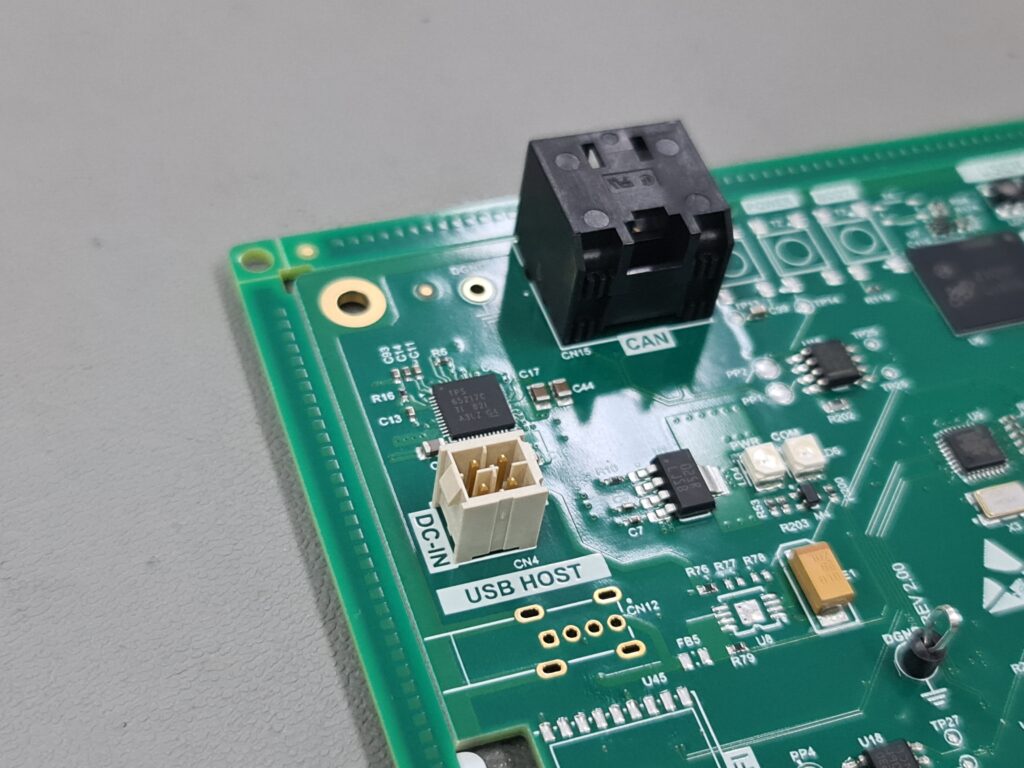

- Hetech has teamed up with EcoJoule to manufacture the PCB boards for the EcoVAR and build the products ready for distribution.

- EcoJoule has quoted that the product has shown to be a success both here and overseas.

- The EcoVar is not only improving the quality of electricity in these areas, but it is also helping grid businesses like Ausgrid work towards a net-zero future.

With the rapid uptake of solar PV, the low voltage residential electricity network is being required to perform in ways it was never originally designed to perform. The main problem being experienced is worsening voltage regulation. The solar PV systems are generating at their maximum during the middle of the day when residential consumption is typically low, this then causes voltage rises on the low voltage networks causing solar inverters to trip, reducing the ability of solar panels to export clean energy. This sustained delivery of excess voltage levels is also diminishing reliability, reducing appliance lifetime and reducing appliance efficiency.

Introducing the EocVAR, the EcoVAR helps to manage grid voltages. The influx of solar changes the way local grids operate. The EcoVAR technology helps improve voltages and increases the ability of solar to export clean energy to the grid. The benefits of this product are felt throughout the whole solar / energy supply chain, with households benefiting from better energy utilisation, higher solar export volumes and lower bills.

Hetech has teamed up with EcoJoule to manufacture the PCB boards for the EcoVar and, build the products ready for distribution. With many installations complete and delivering results in multiple states currently, the EcoVar is predicted to continue to roll out nationally over the coming months.

EcoJoule has quoted that the product has shown to be a success both here and overseas:

“Ausgrid has installed a three phase EcoVAR unit from EcoJoule Energy at Nords Wharf, which has successfully reduced the voltage fluctuation to consumers, also preventing the potential tripping of solar systems and delivering reliable outcomes in the delivery of power.

In the area where the EcoVAR unit has been installed there is a significant increase in the amount of solar energy that can be exported into the grid, virtually eliminating constraints on existing solar customers.”

Not only is the EcoVar improving the quality of electricity in these areas, but it is also helping businesses like Ausgrid work towards a net-zero future.

Ausgrid’s Executive General Manager of Asset Management Junayd Hollis said:

“Ausgrid has a diverse and complex network and we are looking to use innovative technology to improve service quality for all of our communities,” Mr Hollis said.

“That’s why we commenced these trials with the EcoVAR units, to improve customer voltage and quality of electricity supply. This is an integral part of our actions to increase hosting capacity for rooftop solar as well as other Distributed Energy Resources (DER), and reduce costs on our network. In turn this helps de-carbonise the grid and work towards a net-zero future.”

Spiral Automation

The manual nature of the product/reject splitters mean that operators are slow to respond to changes in feed quality.

Vanadium developed an innovative means of automating spiral splitters. This technology (patent pending) now allows for the accurate remote adjustment of each spiral’s product and middlings splitters.

Requirement

To design and manufacture an automation system that integrates into existing mining spiral circuits which will autonomously operate the feed splitters using linear actuators and motor controllers.

Work Performed

Hetech have designed and manufactured several units with fast manufacturing and delivery times to meet the specified requirements. The Spiral Galaxy system is now being utilised in Australian mines. Improving feed quality and efficiency through minimisation of human intervention, risk reduction and improved plant recovery.

“We partnered with Hetech’s engineering team to design and build a mining automation system to be integrated into gravity-fed spiral circuits. Their customer service and professionalism have exceeded my expectations. They consistently deliver within time-frames and even fly out engineers to assist with diagnosing and maintaining products in the field, ensuring the system was operating as expected. I highly recommend Hetech; they have gone beyond their expectations to ensure the best product possible.”

Gerald Van Niekerk, Director – Vanadium Group