News & Events | Page 3 of 8 | Hetech

It’s been a big month here at Hetech, from Land Forces to a new Operations Manager and plenty in between. Here’s a quick recap from October.

Local School Visits Hetech

It’s great to see local teachers facilitating career days such as this. Last week, Hetech welcomed teachers and students from a local high school through Hetech HQ. Mark (Hetech’s Managing Director) showed the group through our manufacturing facility and provided the students with an overview of what a career in electronics could look like.

Shane Kelley Joins Hetech as Operations Manager

Shane comes to Hetech with a wealth of experience and skills. Shane is a highly disciplined, resilient, and experienced Manager with a history of delivering Strategic, Financial and Operational goals through productivity gains, process improvement and inspirational leadership. Shane’s background includes governmental and private leadership positions across various industries, including Manufacturing, Civil Infrastructure, Defence and Government.

Success at Land Forces 2022

Hetech were honoured to be involved and included in the QLD Government stand. It was great to meet with some of the customers and partners face-to-face. As a business, we look forward to growing our capabilities within the local Defence industry through a number of initiatives.

Hetech is pleased to announce that our new Operations Manager, Shane Kelley, has officially started. We’ve given Shane a week to get his feet under the table and now want to introduce Shane to our customers and suppliers.

Shane comes to Hetech with a wealth of experience and skills. Shane is a highly disciplined, resilient, and experienced Manager with a history of delivering Strategic, Financial and Operational goals through productivity gains, process improvement and inspirational leadership. Shane’s background includes governmental and private leadership positions across various industries, including Manufacturing, Civil Infrastructure, Defence and Government.

We got some time today to ask Shane 5 questions that we thought were relevant.

How long have you worked in Electronic manufacturing?

I have worked in Manufacturing for the past five years after many years in Business and Stakeholder management across many sectors, including State government and Tier 1 Organisations.

How did you start your career in the industry?

I started my working life in the Royal Australian Navy, serving as part of the engineering department on HMAS Perth (DDG38), and HMAS Kuttabul (Fleet Maintenance Arm) – before taking on executive/management positions within the QLD State Government (Transport and Main Roads).

My roles have always focused on delivery, and I get my kicks by providing solutions to my customers and navigating the various challenges this entails.

What excites you most about the industry?

I’m excited to support and continue to grow local businesses to develop world-class infrastructure and solutions further. I think there is an excellent opportunity due to the current global climate to build more locally, and there is no reason why Australia shouldn’t lead the way.

Outside of this, I think using technology (machinery) to upskill staff further and produce more complex products will be an exciting journey.

What are the biggest challenges you can see within the industry right now?

Skills shortages are something every industry within Australia (and across the world) is facing at the moment.

I am looking forward to working with Schools, TAFE’s and Universities to increase our talent pool while providing long-term careers to the next generation of kids in new and exciting fields/industries.

Supply chain issues and shortages of parts have meant most businesses have had to pivot and plan significantly ahead. I see Hetech and myself partnering with our customers and suppliers to ensure delivery is as timely and efficient as possible.

Why did you decide to work with Hetech?

Hetech is more than just a traditional manufacturing company, I can see they are innovative and have a great work environment. I can also see that Australian Manufacturing is a growth area that helps build capability and protect Australian assets and interests.

That’s a wrap to Land Forces 2022 in Brisbane. Hetech were honoured to be involved and included in the QLD Government stand. It was great to meet with some of the customers and partners face-to-face. As a business, we look forward to growing our capabilities within the local Defence industry through a number of initiatives, just some of these are:

- AS9100 certification

- Hetech were chosen to take part in the Boeing Capability Up-Lift Program

This year was the largest Land Forces Expo ever held! With over 810 participating exhibitor companies and record attendances. We are looking forward to Land Forces 2023!

Check out our pictures from the 3-day event:

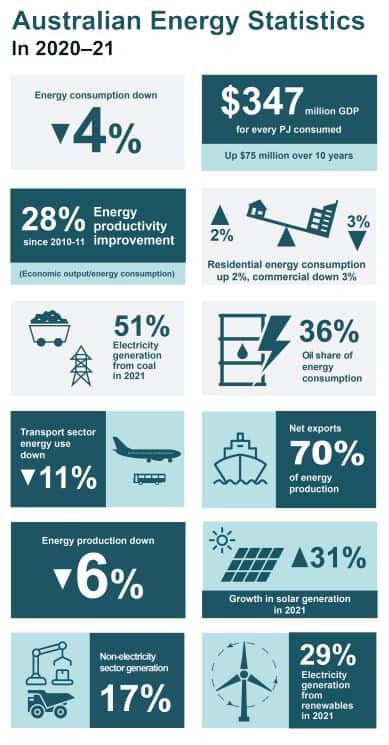

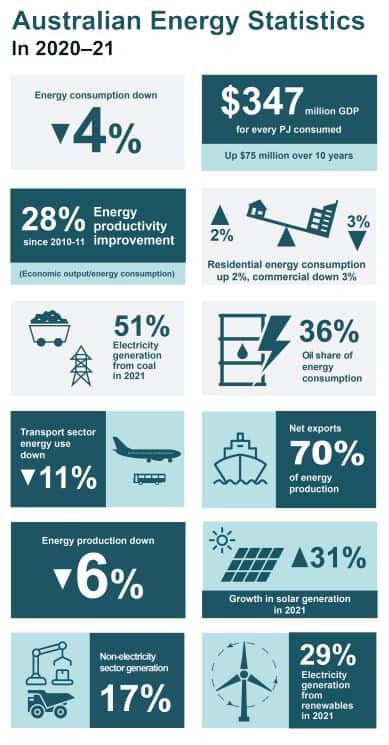

Have you read the 2022 Australian Energy Statistics report?

Released by the Australian Government earlier this month, the Australian Energy Statistics is the authoritative and official source of energy statistics for Australia. This edition contains the latest data for 2020-21.

At Hetech, we are committed to reducing energy usage and finding new and innovative ways to produce and consume energy. Our HQ’s 70KWh solar panel system ensures we are now operating at energy neutrality. On average that’s 42 tonnes of CO2 we save each year.

Some of the highlights from the report are:

- Australia’s energy consumption fell 3.6 per cent in 2020–21 to 5,790 petajoules. With record declines in each of the last two years (largely driven by COVID-19 effects), this took energy consumption below the level of ten years ago (5,910 petajoules).

- Energy use increased slightly in Manufacturing, led by metals and food manufacturing, despite a decline in petroleum refining activity

- Energy production fell 6 per cent in 2020–21 to 18,952 petajoules, with declines in the production of nearly all fossil fuels but an increase in renewable energy production.

- Renewables production increased 10 per cent, almost entirely due to the rapid expansion of solar and wind electricity production, although biomass production also grew modestly with a larger sugar harvest.

- Renewable generation increased 18 per cent in 2020–21, contributing 27 per cent of total generation (71 terawatt hours). Solar and wind contributed 10 and 9 per cent of total generation respectively.

- Renewable generation grew further in the calendar year 2021, to 29 per cent of total generation and 78 terawatt hours, both the highest on record. In the calendar year 2021, solar generation grew 31 per cent and wind generation grew 19 per cent.

Hetech is excited to be working with Boeing on their first-of-type Defence readiness supplier program with 20 Australian small-to-medium enterprises (SMEs) with the knowledge, support and training they need to be defence ready.

Media release from Boeing

BRISBANE, QUEENSLAND, July 26, 2022 – Boeing [NYSE: BA] Australia will deliver an industry first-of-type training program to equip 20 Australian small-to-medium enterprises (SMEs) with the knowledge, support and training they need to be defence ready.

Joined by program delivery partners, The Office of Defence Industry Support from the Department of Defence, AusIndustry and Defence Jobs Queensland, the pilot program will combine resources and industry experts to deliver the best advisory services tailored to each business, as well as mentoring, events and support on defence and cyber maturity.

“We acknowledge the barriers SMEs experience in entering the Defence sector and this unique program intends to break down those barriers to ensure these talented businesses have the tools, support and mentoring they need to be successful,” said Scott Carpendale, vice president and managing director, Boeing Defence Australia.

“This program first continues our efforts to cultivate a vibrant and sustainable Australian Industry Capability supporting a resilient supply chain, which is vital to Boeing Australia’s growth and our nation’s security.”

The first SME cohort covers a range of critical capabilities across air, sea, land, space and cyber domains in the areas of autonomous systems, simulation, prototyping and manufacturing, artificial intelligence and software engineering, and cyber and information security. The businesses include:

- seven majority Indigenous-owned businesses

- three majority women-owned businesses

- three majority veteran owned businesses

- four businesses who are signatories to the ‘Prime Minister’s Veterans’ Employment Program’.

“To have a strong and robust sovereign capability, a diverse supply chain is necessary—our suppliers need to reflect our nation,” said Adam Goodes, founder and CEO of Indigenous Defence & Infrastructure Consortium.

“Diversity breeds creativity and alternative thinking, which will help strengthen Australia’s defence and infrastructure.”

Jasmine Riddle, owner and chief operations officer of JRS Manufacturing – a majority female and veteran-owned business said taking part in the program offered the opportunity to upscale their business following their inclusion in Boeing’s Advanced Defence Aerospace Manufacturing Network.

“The program will give us access to top industry leaders and advisory services and prepare us to take on future work in defence industry,” said Riddle.

Boeing Australia currently has more than 2300 suppliers with an annual spend of over $400 million, and the program’s Federal and State support is designed to create opportunities for Australian SMEs both domestically and through potential global supply chain opportunities.

Last night, Hetech’s Managing Director Mark Steiner joined other CEOs for the 2022 Vinnies CEO Sleepout. So far a total of $8,931,113 has been raised for vital services to support the 116,000+ people homeless across Australia. Mark also exceeded his goal of $5,000, raising $6,676.

The funds raised from the event will ensure Vinnies can continue to help those experiencing homelessness.

“Everyone deserves a safe place to call home. That’s why Vinnies is raising money to provide people experiencing homelessness and people at risk of homelessness with vital access to food and accommodation. We also provide education, counselling, employment and health services to help people overcome poverty in the long term.”

Support Australians who are doing it tough, there is still time to donate.

- Decarbonisation is becoming a top priority for buyers and consumers

- Shell Energy’s report has highlighted a range of energy-saving and emissions-reduction solutions

- A 2022 Cohort Business Decarbonisation Pathway has been developed

Just this year, Shell Energy released a report – Advancing Renewables in the Manufacturing Sector. The projects aim was to develop a web-based, digital, education platform that shared data, analysis and insights generated from energy assessments at twenty manufacturing sites in Queensland, with the idea to help overcome investment barriers that exist for the uptake of renewable energy and energy productivity improvement initiatives in the manufacturing sector.

The report highlighted many key energy-saving and emissions-reduction solutions, some easier to implement than others, below is a snapshot of some of these solutions:

- Electricity and gas efficiency can save between 10-15% consumption:

- Lighting upgrades

- Variable Speed Drives

- Heat (and cooling) recovery

- Burner controls

- Compressed air

- Electrification of gas based process heat

- Onsite renewable energy generation (solar + BESS)

At Hetech we have been committed to decarbonisation and reducing our carbon footprint, last year we began to change the way we consumed energy, reducing our carbon footprint by installing a huge 70KWh solar panel system! Since installing the solar panels, we are now operating at energy neutrality. On average that’s 42 tonnes of CO2 that we are saving each year. Another focus has been on Design for the Environment (DfE), an initiative that looks at the lifecycle of a product, this includes three stages:

1. Production

When efficient manufacturing processes are used in production, more sustainable products can be made. The use of the right materials is a big part of this phase. A reduction of the variety of materials used can reduce pollution, energy consumed, and the cost of production.

2. Consumption

Products are designed to use only enough power in its current state. This can be achieved by utilizing sleep modes, using batteries that lose energy slowly, combining functions in the integrated circuits, turning off segments of the circuit that are not in use, etc.

3. Destruction

At the end of their lifecycle, electronics must be thrown away, reused, or recycled. However, most electronics are not repairable, making them difficult to reuse. DfE eliminates the effect of this on the environment by recycling the components in factories to create new raw materials.

A 2022 Cohort Business Decarbonisation Pathway has been developed, the government-funded business growth and capability-building initiative’s aim is to enable Australian SMEs to future-proof their business by identifying decarbonisation pathways and becoming net zero certified. Involvement in this project can provide eligible businesses with access to industry networks, expert resources and up to $20,000 (matched) grant funding to progress your business goal.

We are well in truly back in the swing of face to face events.

It’s been a busy few weeks of events, Mark Steiner attended a number of events over the last few weeks with record numbers at some.

Here’s a snapshot of the past events.

Australian Manufacturing Week, Sydney

Potentially the biggest Australian Manufacturing Week to date is being held in Sydney right now.

Mark Steiner is at the event and said, “The national manufacturing expo (NMW) is on again after a 3-year break. It’s great to see so many new advanced machines that will help Hetech Pty Ltd automate and grow. We also caught up with our partner ECI who is helping us implement our new ERP system called M1. Better, faster and customer focus is the motto here. Stay tuned.”

Austmine Mining Innovation Roadshow, Brisbane

Held at the W Brisbane, the theme of the event focused on “Harnessing Intelligence: Drivers of Social Value “Optimising our People, Technology, and Partnerships”.

Office of Defence Industry Support (ODIS), Brisbane

Another great forum today focusing on ‘Readiness and Resilience’.

Mark Steiner attended the event and said ‘The forum was a great opportunity to hear from Defence industry leaders, key defence contractors and business experts about our business readiness and how to best prepare for entry into the Defence market.”

On a recent business trip to Sydney, Mark said ‘Walking through Sydney CBD after a successful marine defence exhibition I came across homelessness on every corner, this did not sit well with me. Therefore I’m going to sleep rough for one night and hopefully raise $5,000 for the Vinnies homeless support campaign.’

In place of End of Financial Year gifts this year Hetech Pty Ltd has decided to support our Managing Director Mark Steiner in the annual CEO Sleepout.

Below are just some of the ways your donations can help those in need this winter:

$55 can help feed a family for a day

$120 can help keep a family warm this winter

$300 can help relocate a person sleeping rough to accommodation services

Every night, thousands of Australians experience homelessness. But it doesn’t have to be that way. This year I’m taking part in the Vinnies CEO Sleepout to raise money for the St Vincent de Paul Society to support Australians in need. For one night, I’ll be sleeping outside as part of an eye-opening experience to raise awareness and bring home the realities of homelessness.

To help break the devastating cycle of homelessness, I need your support. Will you help me to reach my target?

– Hetech’s second manufacturing facility is now open.

– Now the owner of the state-of-the-art PCB cleaning machine – Ultra 2012LE.

– Developing young talent through our Hetech apprentice program.

With a second manufacturing facility recently opened, Hetech is committed to investing in the growth and expansion of the manufacturing industry in Australia.

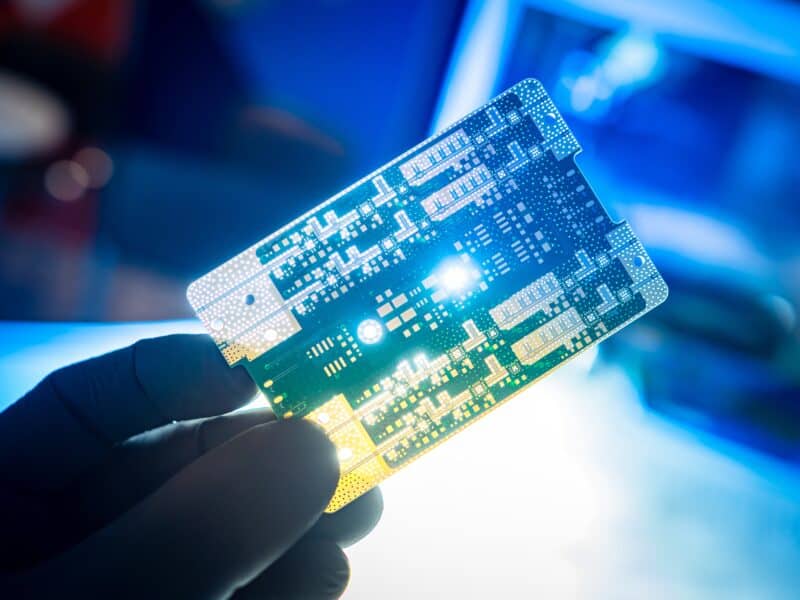

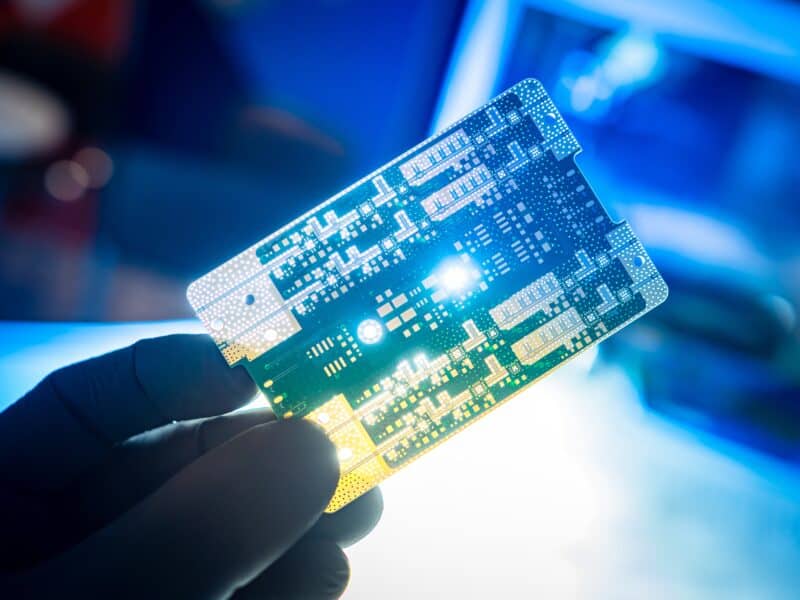

At Hetech we strongly agree with adopting new technologies and ensuring we have state-of-the-art machinery. Recently, we purchased a PCB cleaning machine – Ultra 2012LE, Vapor Degreaser.

The Ultra 2012LE is a leader in the field of Printed Circuit Board cleaning. PCBs are sometimes exposed to conditions like high humidity and extreme temperatures, they also need to last for sometimes decades, and because of this, it is vital PCBs function without fail.

With all of this in mind, what happens at the cleaning stage of production is vital, the Ultra 2012LE improves PCB reliability through the cleaning process. For a PCB to be reliable, a number of factors play a pivotal role, just some of the threats to its reliability include:

- Production contaminants such as dust and soils on a PCB run a risk of malfunction.

- Small PCBs and complex PCBs with multilayered layouts can be challenging to clean at the level required.

Hetech’s new Vapor degreaser machine provides state-of-the-art cleaning for PCBs. Vapor degreasing uses cleaning fluid immersion, combined with vapour rinsing and vapour drying, to clean PCBs down to the submicron range removing all types of residue.

The cleaning fluid used has a low surface tension allowing it to permeate the entire board, including under and in-between tightly-spaced and low-mounted components. Vapour degreasers recycle and reuse the cleaning fluid for hundreds of hours before the fluid is refreshed, making it a cost-effective and environmentally sound cleaning method.

Here is a short video explaining some of the features and benefits of our new machine: