News & Events | Page 2 of 8 | Hetech

We are excited to introduce you to our new HR team member, Larissa. Larissa is joining us to help support and shape the growth of the business.

As the business continues to expand, we recognise the importance of having a dedicated HR professional on board to ensure we are providing a positive work environment. Larissa brings a wealth of experience and knowledge to the role, and we are confident she will significantly impact the business.

It’s been a few weeks since Larissa joined Hetech, and now that she has had a chance to get her feet under the desk, we thought it would be a great time to chat with her.

1. What inspired you to pursue a career in HR?

I have always found it a fascinating topic given working conditions impacts most of the population and how much time we as humans spend working.

I initially pursued studies in human resources as I found understanding Australia’s employment relations framework was critical in every job I undertook.

I then decided to pursue my Juris Doctor with a sole focus on employment law to do a deep dive into the legalities of the employment landscape. This really came in handy when assisting clients to navigate through the pandemic.

Overall, I want to ensure that employees and businesses are aware of their rights and responsibilities and help foster great relationships and communication between both. Ensuring employees feel seen and supported is my goal and focus.

2. What are your first impressions of the company culture and work environment?

From the moment I sat for my interview, I felt very welcomed at Hetech. The company culture feels like a big family. Everyone has been very supportive especially as this role is new and so is my experience in internal HR.

Our work environment is busy but supportive. Hetech offers a wonderful amount of flexibility and it’s really appreciated.

3. What do you think are the most important qualities for an HR professional to possess?

Communication and listening skills – identifying and knowing how to overcome communication barriers between the employee and management,

Compassion – ensuring employees feel seen and supported.

Organisation skills – understanding the importance of setting frameworks, and processes to ensure legislative compliance.

4. What do you think sets this company apart from others you’ve worked with in the past, and how do you plan to contribute to its success?

Having previously been in consultancy-based work I have always been on the outside – completing a specific project for a specific client and moving on to the client and project. Hetech is my first opportunity to provide internal HR support to one company.

I plan on contributing to its success by engaging with the team, so I understand the ins and outs of the Company. This will allow me to foster growth and safeguard the business.

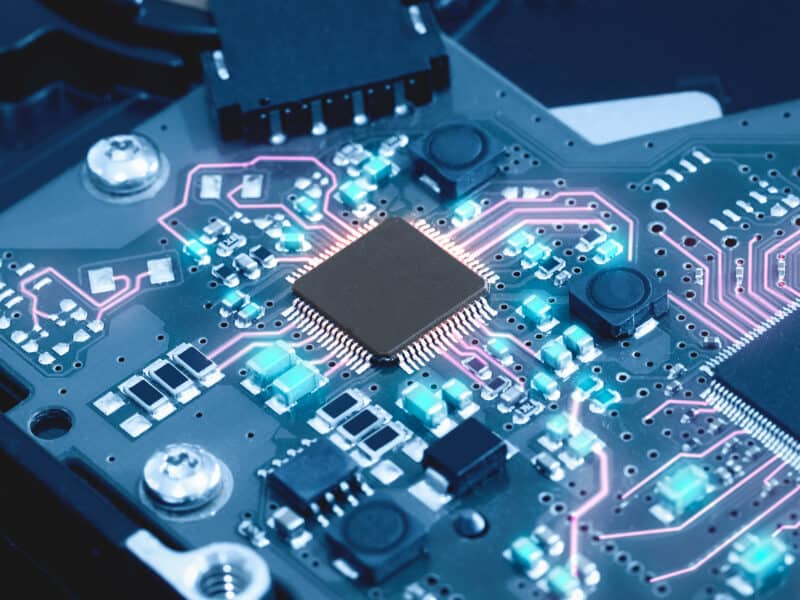

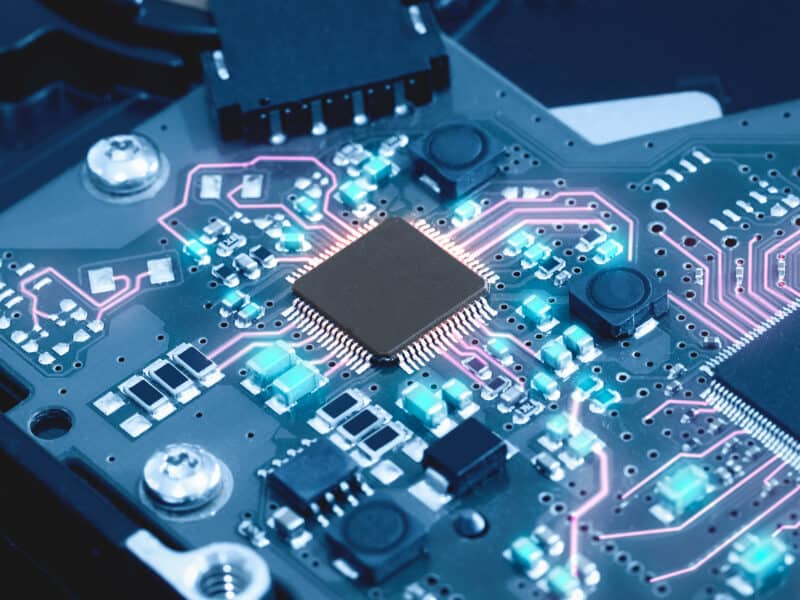

Almost all products consumers use day to day have some form of electronic component or system, and electronic manufacturing plays an integral part in the creation of these products. Electronic manufacturing for industrial designers involves the creation of components, products and systems, and their assembly into finished products. Without proper electronic manufacturing, the design of a product may not translate to a functional and reliable product.

Why Hetech?

Hetech partners with Industrial Designers, working with them on all parts of the manufacturing process from testing to production, Hetech has the experience and resources to ensure a product’s success.

Just some of the critical stages where Hetech can help in the electronic manufacturing process are:

- Design – Creation of the product design, including all electronic components.

- PCB Layout – The design of the printed circuit board is created based on electronic components.

- Fabrication – PCB is fabricated based on the design, and the electronic components are placed on the board.

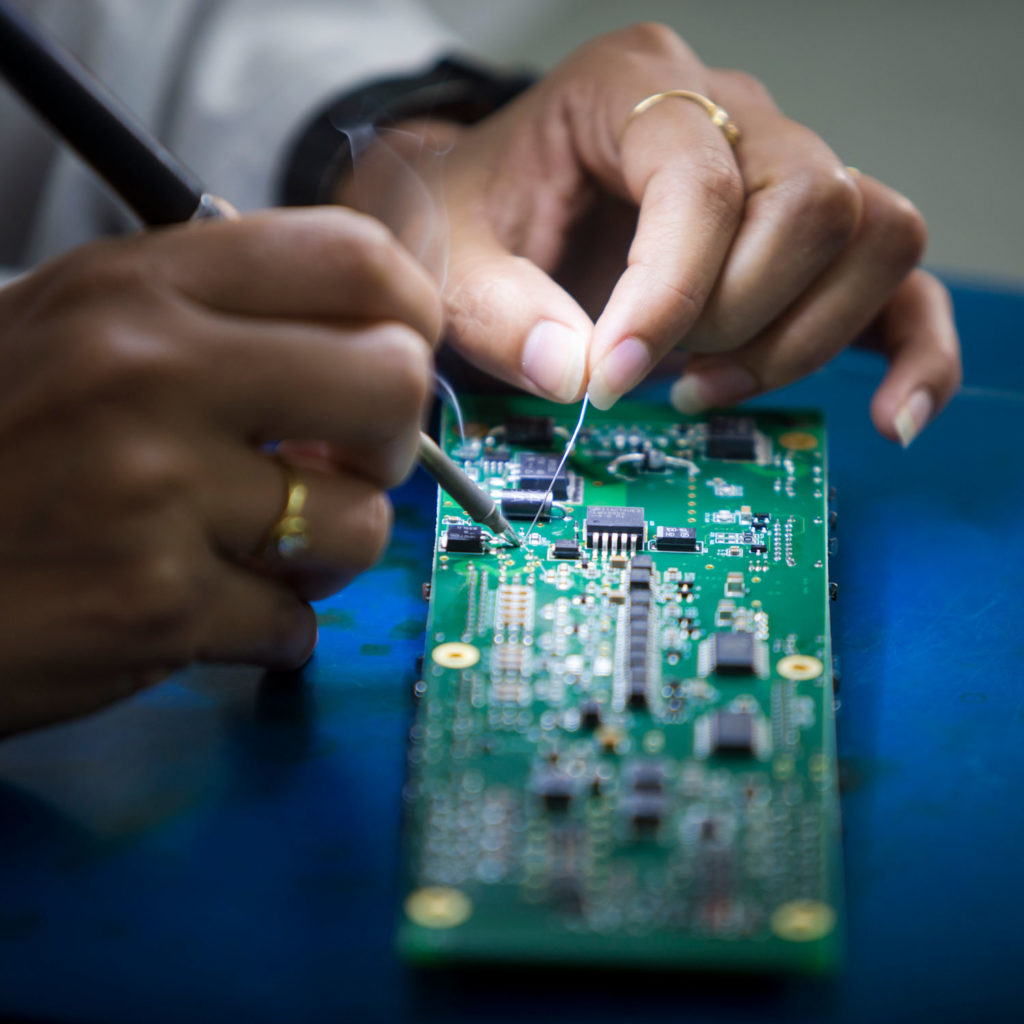

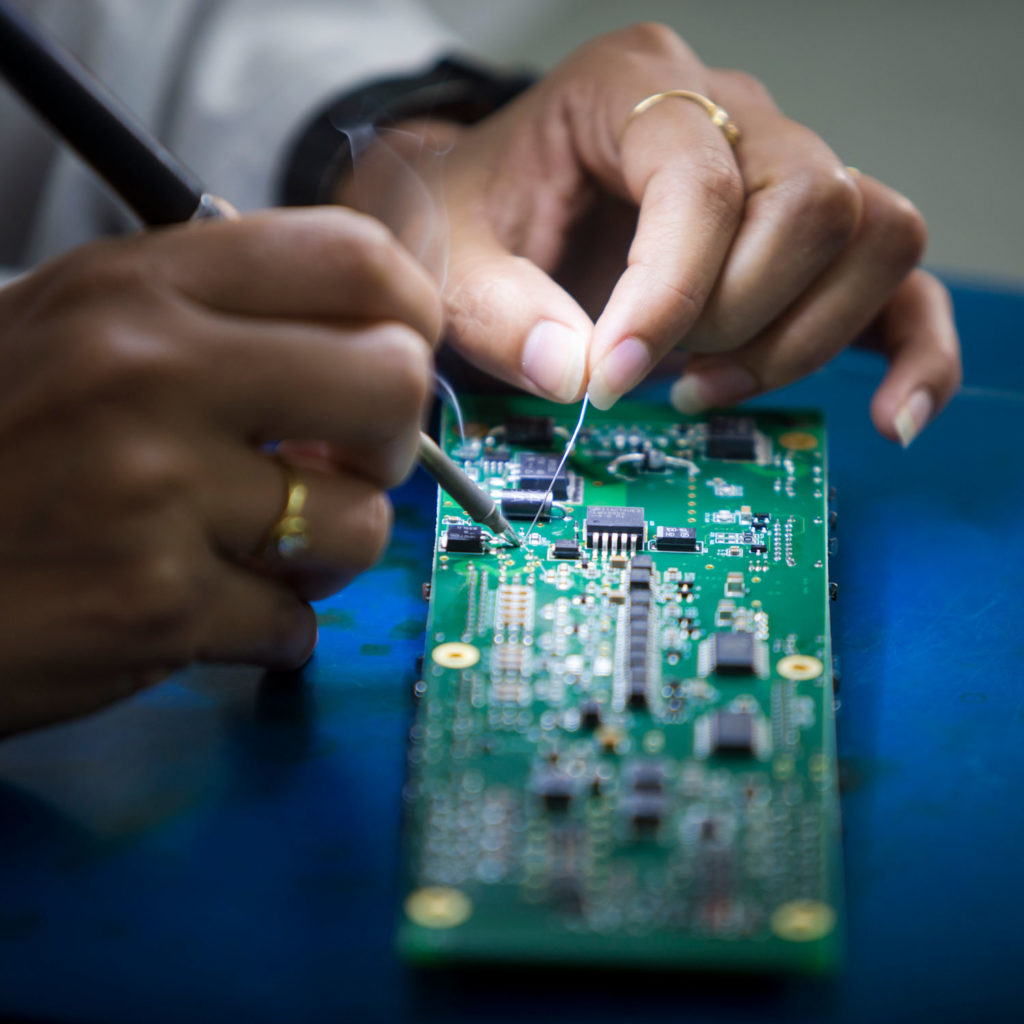

- Assembly – Electronic components are soldered onto the PCB.

- Testing – The finished product is tested to ensure it functions correctly prior to mass production.

As a medium-sized manufacturer, Hetech can manufacture electronic products on both a smaller and larger scale. With experience in both commercial and niche markets, Hetech uses resources efficiently and is quickly able to adapt to changes in demand, all while ensuring quality control and delivering on time and within budget.

Hetech has been designing and manufacturing Printed Circuit Boards (PCB’s) for close to 30 years, our team is made up of experienced engineers and technicians with a multitude of experience.

Just some of the reasons our customers choose us to manufacture their PCB’s are:

- Experience: We have been in the electronic manufacturing industry for over 30 years, bringing a wealth of experience and knowledge in both the design and build of PCB’s.

- Quality: We are AS9100 and ISO9001-accredited, building to J-STD-001/IPC-A-610 class 3 standards and are a part of DISP (EL), providing for full traceability and more accurate processes for our customers. Due to our high level of quality control and accreditations, we have a reputation for delivering high-quality products. This is essential when it comes to PCB Manufacturing. Some of the printed circuit boards our team are responsible for manufacturing will be heading to space with our customer Gilmour Space.

- Customisation: We can customise PCBs to meet your specific requirements, our team of engineers can design, prototype, and manufacture PCBs that are unique to your business.

- Technology: We manufacture our PCBs using the latest available technology and equipment. This allows us to manufacture quickly and efficiently while ensuring the quality is not compromised.

- Customer service: We aim to exceed our customers’ expectations, from initial consultation to product delivery our team are with you every step of the way.

To view some of our work in this space head to our website.

Or, to contact us on how we can partner with you to optimise your product, please reach out to us via the button below.

We’ve been hearing a lot about Australian Space in the media lately, but what is involved in this complex sector and how is it helping us here on earth?

International Space exploration is working to develop advanced technologies that help everyday individuals here on earth, as outlined by NASA just some of these are:

1. Supporting water purification efforts worldwide

Joint collaborations between aid organizations and NASA technology show just how effectively space research can adapt to contribute answers to global problems. Using technology developed for the space station, at-risk areas can gain access to advanced water filtration and purification systems, making a life-saving difference in these communities.

2. Bringing space station ultrasound to the ends of the Earth

Medical care has become more accessible in remote regions by the use of small ultrasound units, telemedicine, and remote guidance techniques, just like those used for people living aboard the international space station.

3. Making inoperable tumours operable with a robotic arm

The same technology that went into developing neuroArm, the world’s first robot capable of performing surgery inside magnetic resonance machines, was born from the Canadarm, Canadarm2 and Dextre, the Canadian Space Agency’s family of space robots responsible for performing the heavy lifting and maintenance aboard the International Space Station.

4. Monitoring natural disasters from space

An imaging system used in space captures photographs of Earth from space for use in developing countries affected by natural disasters. Images from orbit can help with rapid response efforts to floods, fires, volcanic eruptions, deforestation, harmful algal blooms, and other types of natural events. Since the station passes over more than 90% of the Earth’s populated areas every 24 hours, it is available to provide imagery to developing nations quickly, collecting up to 1,000 images per day.

Plus, so much more, you can read more about this here:

Hetech has been providing electronic design and manufacturing services to this sector for some time now and, we look forward to further advances in technology thanks to the space sector.

Space Technologies

Space technologies and services benefit all Australians. Several of the daily conveniences we have come to expect, operate thanks to Space technology, just some of these are:

- Weather forecasting

- Agriculture

- Remote communications

- Internet access

- Online banking

- GPS, plus much more.

Hetech provides PCB manufacturing services to Gilmour Space

Gilmour Space has been in the news a lot recently due to the great work they are doing within the Australian Space sector. Founded by Adam and James Gilmour, Gilmour Space is the leading provider of Australian-made launch vehicles and satellite platforms.

Hetech has been manufacturing Gilmour-designed boards for their Remote Data Acquisition Units. The boards go into all stages of the 3-stage launch vehicle. They are used to sample sensor data from most of the subsystems on the rocket to do health monitoring through a Telemetry link back to the ground.

Recently, Mark dropped by Gilmour Space Headquarters and met with Gilmour’s Director and Head of Communications, Michelle Gilmour. We are excited about what is on the horizon, watch this space!

There are several exciting projects on the horizon for the Australian Space industry. To keep up to date with what Gilmour Space is doing in this space, simply head to their website.

Mark will be visiting Adelaide, Sydney and Melbourne this month, if you’d like to touch base with Mark please follow the instructions below.

Adelaide

Tuesday, 7th February

Wednesday, 8th February

Sydney

Tuesday, 15th February

Wednesday, 16th February

Melbourne

Tuesday, 28th February

> Friday, 3rd March

What is a PCB?

Printed Circuit Boards (PCBs) are the backbone of all major electronics. You can find PCBs in nearly all computational electronics, from simple devices like digital clocks, and calculators to more advanced devices including computers, smartphones and cars.

A printed circuit board (PCB) is an electronic assembly that uses copper conductors to create electrical connections between components. A printed circuit board design must include a specific set of steps that aligns with the manufacturing process, integrated circuit packaging, and the structure of the bare circuit board.

In short, PCBs tell the electricity where to go, bringing your electronics to life.

What to do if you need a PCB in your product?

1. Specification: The first step in the design process is to develop a clear specification of your product. Our design team will work with you to create your specification. This is the most important step as it will ensure that both parties have a clear scope and outcome for the project.

2. Proof of Concept: Our engineers will then use off-the-shelf development kits to develop a “proof of concept”. This stage of the design will determine the types of technology used to achieve the goals of the product and whether the product concept is viable within the given budget and time frame.

3. Schematic Capture & Design: The proof of concept will then be captured as a schematic design. It shows all the components required and how they are connected.

4. PCB Component Placement and Routing: Using PCB design software such as Altium, all the required components on the functional schematic design will be placed on a digital PCB board.

5. Design for Manufacture: Hetech will always ensure that your product is designed to conform to modern manufacturing practices. As an in-house Design and Manufacturing company, we have access to valuable direct manufacturing feedback. This will assist in reducing your manufacturing overheads.

6. Final Delivery: After extensive testing and revisions and all parties are happy, we have a final product!

- Hetech worked with Boeing Defence Australia on their Project Currawong, delivering part of the battlespace communication system.

- Hetech is now AS9100 accredited.

As a growing and constantly evolving business, Hetech are always working to improve our business capabilities, most recently Hetech has become AS9100 certified and moved to a new ERP system to improve our day-to-day operations. With over 30 years in business, we have worked with a variety of industries, partnering with businesses to design and manufacture electronics for their products.

Working heavily within defence over the last few years has seen our business capabilities grow exponentially. Boeing Defence Australia was one of our first clients in this sector and we have enjoyed the partnership and years of working together.

Our team worked with Boeing Defence Australia to deliver part of a battlespace communication system within a tight and dynamic time frame, building both the prototype and production units. Project Currawong saw the team manufacture two sub-systems for the Network Access Module (NAM) – a rugged hardware case that provides the power and services needed to enable secure communications.

Hetech supplied the following components to Boeing Defence Australia on this project:

- Universal Power Supply Module

- Low Side NAM Signal Entry Panel

- High Side NAM Signal Entry Panel

- Subscriber Access Interface Signal Entry Panel

- Deployable Data Centre Assembly Signal Entry Panel

- Network Breakout Unit

- Deployable Data Centre Assembly Power Supply Module

- Deployable Data Centre Assembly Dual Red Backplane

- Deployable Data Centre Assembly Red/Black Backplane

- Port Breakout Module

Bronwyn Morris, Boeing Defence Australia’s Field Hardware lead who worked closely with Hetech on Project Currawong said,

“Hetech’s electronics manufacturing and project management capabilities have been and continue to be integral to the success of project Currawong. Hetech has consistently manufactured and supplied hundreds of complex, ruggedised hardware modules for delivery to the Australian Army. Hetech’s passion, honesty and integrity has been one of the key drivers in assisting the Currawong Project to meet challenging delivery milestones. In the spirit of fostering true collaboration and transparency in business combined with an innovative and proactive engineering regime, Hetech has assisted in ensuring Project Currawong success to date, on schedule and on budget.”

Hetech is constantly investing in growth, just some of our most recent upgrades include:

Equipment Upgrades:

- New SMT Pick and Place machine to provide the best quality PCB assemblies for defence companies such as Boeing Defence Australia, Hetech invested in a new Pick and Place machine. The purchase has proven to build PCBs more reliably and also reduced assembly time by almost half, a huge boost in production efficiency.

- Conformal coating machines. Due to growth in the defence sector within the company, thanks to Boeing Defence Australia, Hetech won the “Made in Queensland” state government grant to invest in a state-of-the-art conformal coating machine. The new machine automatically sprays PCB boards with a protective coating, ensuring they can withstand the harsh environments commonly seen in the defence industry. (See conformal_coating_article.pdf).

- Automatic Optical Inspection (AOI) Taking advantage of the Defence Capability Grant, Hetech purchased an AOI (automated optical inspection) machine that is used to visually inspect printed circuit boards. The machine uses a camera to autonomously scan devices and test for both catastrophic failures (such as a missing part) and quality defects (such as incorrect size or shape).

- New IT Infrastructure with Network Security Upgrade We believe, if you are to work in the defence sector as a supplier, you have to invest in IT security. Hetech has heavily invested in new IT infrastructure, enabling a tighter security protocol for client data and allowing for better communication & coordination throughout the company.

- AS9100 accredited, the accreditation demonstrates our ability to consistently provide products that meet customer and regulatory requirements for Aviation, Space and Defence Organisations.

- Moved to M1 ERP system, providing advanced capabilities in materials and labour planning, better component tracking, enhanced shopfloor functions, plus much more.

The Hetech team is continually working to upskill and we have been focused on growing the team, bringing on new technicians that specialise in a variety of areas, including:

- Increased our staff by an extra 4 people.

- New QA Manager: Audits conducted at Hetech from companies such as Boeing Defence Australia have prompted a new position within the company.

Due to growth and investment into Australian SMEs from clients such as Boeing Defence Australia, Hetech is investing in STEM programs to help build a new generation of electronics engineers and manufacturers. Another step towards creating a globally competitive electronics hub in Queensland. We have worked with the likes of Park Ridge School, QMI & Griffith to expose students to the growing world of local electronics manufacturing (https://www.hetech.com.au/students-spend-an-afternoon-with-hetech/).

Upgrading and improving our security certifications and systems, along with ensuring our team is trained in the requirements of a secure workplace is something that we are constantly reviewing.

New Certifications

Hetech is an AS9100 and ISO9001-accredited company and builds to J-STD-001/IPC-A-610 class 3 standards, along with being a part of DISP (EL). Hetech has recently become AS9100 accreditation, which is an acceleration of its current accreditation and will allow us to win more business with Boeing Defence Australia and other Defence Primes, as a consequence employ more staff for work in the Defence and Aerospace Sectors.

Steve who has worked heavily within the industry says:

”Working with BDA on Project Currawong, has been an amazing success story for Hetech and we are very proud of our continued participation in it.

It is encouraging to see that BDA are actively helping Companies like Hetech to go from a Small to a Medium sized company and we will continue to work together to grow our capabilities and invest in the future and ensure that Australia has a SIC with a large AIC element.

For Project Currawong BDA took a unique and very flexible supplier-centric approach and adopted the Boeing mantra of collaboration across their supply chain partners, actively working with the SME sector, bringing together Companies in the same industry sectors, to work as a team and delivering different modules across the Currawong Platform.

It has been an incredible journey. Thank you to all in the Project Currawong Team for giving Hetech this opportunity.”

As we look to the future of our work within the defence industry, we see further investments in our capabilities to ensure we provide our clients with the best possible service and products.

Planned future investments:

- Second SMT line As Hetech grows, we will require a 2nd SMT line in order to continue building our customer base and deliver future projects without compromising speed and quality for our current customers.

- X-RAY machine (AXI) Much like an AOI machine, X-Ray machines are used in manufacturing to inspect the hidden features of target objects or products (Such as PCB assemblies). Nowadays, X-ray inspection is widely used in lots of applications such as medical, industrial control, and aerospace. A further investment was triggered to ensure we will provide quality assemblies for companies such as Boeing Defence Australia.

- AS9100 accreditation is an aerospace standard

- The standard works to improve quality, cost, and delivery performance

We are proud to share that we have recently received our AS9100 accreditation. The AS9100 accreditation is an aerospace standard that was released by the International Aerospace Quality Group, the accreditation demonstrates our ability to consistently provide products that meet customer and regulatory requirements for Aviation, Space and Defence Organisations. The standard works to improve quality, cost, and delivery performance.

Hetech’s Managing Director, Mark Steiner said of the new certification, “The achievement of AS9100 will enable Hetech to offer its design and manufacturing services to a range of new customers in various markets. The traceability aspect of the standard combined with the introduction of a new ERP system will enhance the level of service to all our customers. This is especially important in the current situation where parts are hard to find or on very long lead times. It will also help us maintain and exceed our current excellence in quality and customer service.”

Benefits for our customers

It’s not only customers in the mentioned industries that will benefit from our new accreditation. For Hetech’s customers from all sectors, gaining this accreditation will provide benefits as Hetech continues to improve the way we operate. Some of these benefits include:

- Higher level of traceability in materials and processes

- Process-driven risk management

- A greater level of supplier accountability

- Improved efficiencies and continual improvements in Hetech’s day-to-day processes

- High-end product quality

- Product safety and reliability

- Higher level of customer satisfaction

Alan Grant, Hetech’s Quality Manager who worked closely on the accreditation process said, ‘We had a very positive experience with our certification body and lead auditor. Engaging a specialist consultant to assist in gap analysis as well as implementation greatly contributed to our success. Hetech had already adopted many of the core principles of AS9100 in our quality system (ISO) prior to the accreditation process, this has added to the maturity of our AQMS. Our employee’s commitment, dedication, professionalism and pride in doing work for the aerospace-defence industry is why we were so successful in attaining the accreditation.’

Contact us if you’d like to find out more.

With the recent cyber-attacks on Australian businesses, it is more important than ever to stay on top of your cyber security both personally and professionally.

At Hetech we take many steps to ensure our customer data is protected, did you know we are part of the Defence Industry Security Program?

The program supports Australian businesses, addressing risks associated with providing services, products, or capabilities to the Australian Defence Organisation.

The program is intended to address and protect the Defence supply chain from security vulnerabilities by assessing the business’s processes, procedures, information technology and cyber security, physical security and personnel security.

This program provides a layer of protection, not just for Hetech’s Defence customers but for all of our customers from every industry. The program improves resilience, security and assurance of our sourcing arrangements.

We protect our customer’s data

- Having an external IT company manage IT/Cyber – security issues.

- Keep mission-critical software (ERP) local, not in the cloud.

- Annual staff training.

- Sporadic spam email checks to internal staff, this is then reviewed and discussed with staff on what to look out for spam.

- Use external “friendly hackers” to see where vulnerabilities (if any) are in our system.

- Keep up to date with ongoing developments in cyberspace.

If you have any questions feel free to reach out to us.