Blog

When venturing into the realm of electronic manufacturing with a new product, prototype testing might seem unnecessary. If you’re confident in your design and eager to expedite your product’s entry into the industrial market, creating a prototype may feel like an unnecessary step. However, upon closer examination, we’ll elucidate the critical role and numerous advantages of prototyping in electronic manufacturing for industrial products.

What is a prototype?

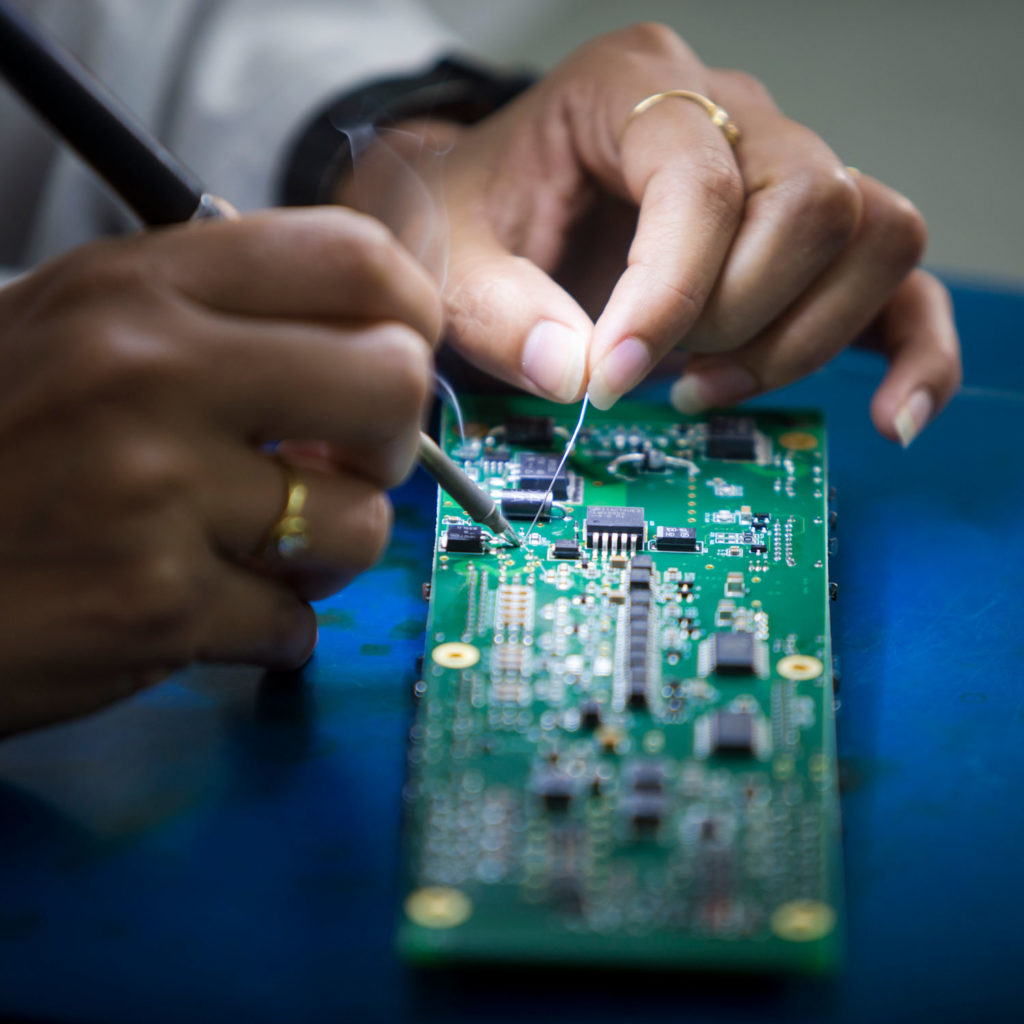

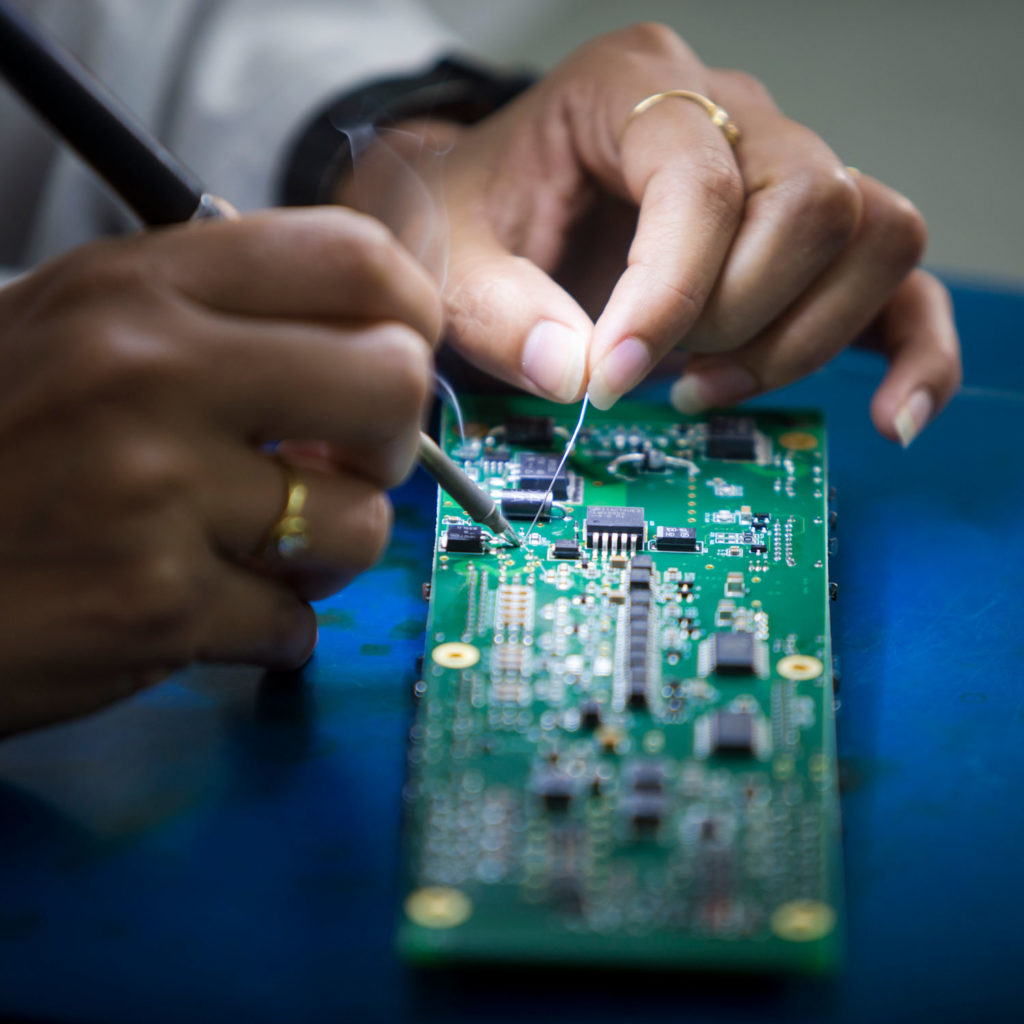

A prototype is an early sample or model of a product that is usually intended for mass creation. For example, a prototype of a circuit board may be created to ensure the design of the circuit board is perfect and the circuit board is able to fulfil its intended purpose.

Why is a prototype useful?

Prototypes play a vital role in electronic manufacturing by detecting defects or minor errors in a product’s design early on. This enables design teams to efficiently correct mistakes and prevent costly mass production of flawed products.

Moreover, multiple prototypes with different components help design teams select the most effective design. These prototypes can also be presented to investors or potential clients, facilitating funding or sales prior to large-scale electronic manufacturing.

Additionally, prototypes undergo rigorous environmental stress testing to ensure reliability in high-pressure industrial environments. Without this testing, designers cannot have confidence in the quality, durability, or accuracy of their electronic manufacturing products

What happens after a prototype is created?

After a prototype is created, and subject to any tests or trials necessary, the prototype can be adapted or upgraded with new assembly components if required. This will ensure the final product that is brought to market is the most efficient and effective version of the product possible.

Hetech is your electronics design and manufacturing partner. If you’d like to learn more about prototypes, or any other stage in our design and manufacturing process, get in touch with us today!

Hetech has been pioneering renewable technology for a long time. We believe looking after the environment doesn’t have to come at a cost to technological advancements. Electronics are now found in many advanced applications, IoT (internet of things) and AI are helping to offer better and more comprehensive solutions for the future. At Hetech, we believe we can make a difference, reach out to us and have a chat with us about your ideas and how we can assist.

Recently, Sustanble Review has released its top 10 green-tech innovations.

So what are the Top 10 Green Technology Innovations?

We’ve summarised these below for you:

#1: Solar Desalination

A promising solution to water shortages, desertification, and hunger using solar energy to desalinate salt water. Companies like Elemental Water Makers are leading the way in implementing solar desalination projects globally, providing affordable, safe, reliable, and fossil-free water solutions.

#2: Green Architecture

Green architecture minimises environmental impact through efficient design, focusing on resource use, waste reduction, and energy efficiency. Companies like Apple, Google, and Microsoft demonstrate this approach with features such as solar panels, smart systems, and green roofs, showcasing commitment to sustainability.

#3: Vertical Farming and Hydroponics

Vertical farming and hydroponics revolutionise agriculture by producing high-quality food in limited spaces and challenging climates. This sustainable solution reduces transportation needs and supports local food sources like microgreens for nearby restaurants.

#4: Wind Power

Wind power, a key renewable energy source, uses the wind to generate electricity. Technological advancements are increasing its efficiency and scalability, offering immense potential for clean energy production. Offshore wind farms, situated where winds are stronger and steadier, contribute significantly to reducing greenhouse gases and fossil fuel dependence.

#5: Electric Vehicles

Transportation pollution from fossil fuels is a concern, but green cars like electric vehicles (EVs) offer a cleaner solution. EVs produce zero emissions, thanks to advancements in battery technology, making them practical and accessible.

#6: Plant-based Packaging

Plant-based packaging provides a sustainable alternative to plastic, reducing waste and ocean pollution. Avantium, a Dutch company, produces recyclable and degradable plant-based plastic called PEF from bio-based sources. PEF offers significant greenhouse gas reduction potential and is a promising option for eco-friendly packaging in various industries.

#7: Sustainable Phones

Smartphones pose environmental concerns due to CO2 emissions and harmful materials like lead and mercury. Fairphone and Teracube address these issues by designing phones with lower environmental impact and social responsibility.

#8: E-waste Recycling

E-waste, comprising discarded electronics, poses environmental hazards but also holds valuable resources. Advances in recycling methods, like automated dismantling and sorting, are improving safety and efficiency in handling e-waste.

#9: Carbon Capture and Storage Technology

Carbon Capture and Storage (CCS) technology is essential for reducing carbon dioxide emissions from industrial processes and power plants by capturing and storing CO2 underground. Major companies like ExxonMobil, Shell, Equinor, and Occidental are investing in CCS research and projects, recognising its significance in combatting climate change and fostering sustainability.

#10: Nuclear Energy and Fuel Cells

Nuclear energy, though controversial due to waste management and safety concerns, offers a low-carbon energy option with advancements in technology and safety measures. Fuel cells, utilising hydrogen and oxygen to generate electricity with water as the only byproduct, present a promising green technology for clean and efficient energy in diverse applications like transportation and power generation.

Hetech is proud to be an environmentally sustainable company, and we are continually seeking new avenues for growth within the renewable energy sector. As electronic systems play an integral role in various applications, ranging from electric vehicles and scooters to energy management and battery technologies, we recognise the immense potential for reducing carbon emissions through technological innovation.

Our team is enthusiastic about leveraging our expertise to develop solutions that minimize environmental impact while maximizing efficiency and performance. With each advancement, we embark on a journey of discovery, this comes with new research and development initiatives that push the boundaries of what’s possible in sustainable technology.

The recent Everything Electric expo served as a catalyst for our exploration of emerging opportunities within the renewable energy market. By participating in this event, we gained valuable insights and forged strategic partnerships to further strengthen our presence in this dynamic industry.

The Everything Electric expo, is renowned as the premier platform for showcasing advancements in home energy and electric vehicles. Beyond Electric Vehicles of diverse configurations and Home Energy solutions, the expo highlighted the collective effort to accelerate the transition towards cleaner, more sustainable energy systems.

As we look ahead, we are excited about the evolution of the renewable energy landscape in the years to come. Our commitment to driving positive change remains unwavering, and we invite you to stay connected with us as we unveil groundbreaking initiatives in this space.

- IoT and digitalisation significance in electronic manufacturing services for the defence industry.

- Trends in the Australian EMS Industry 2023

- Current electronic manufacturing challenges in Australia

2023 has been a big year for the electronics manufacturing industry. Below we check in on how the Internet of Things (IoT) is impacting the market, the challenges we face in the electronics industry within Australia, and how we leverage upcoming technologies to adapt to the latest trends in the electronics manufacturing services industry (EMS).

The Internet of Things and Digitalisation

IoT has shown huge market potential in the electronics manufacturing services industry. As Hetech delivers electronic manufacturing to the Defence industry, the risk of cyber-attacks and manufacturing efficiency is always at the forefront. IoT helps to identify and improve cyber security, which includes reducing counterfeit electronic components and cyber-attacks among electrical components suppliers.

To meet these requirements, the implementation of digitalisation is crucial to increasing volume and improving efficiency. That being said, cyber-security measures in sensitive processes such as PCB assembly, conformal coating, and data security is crucial for digitalisation. Both electronics manufacturing and material inventories are impacted by the rising trends in digitalisation, which aim to effectively reduce costs and emissions.

Trends seen in Australia for 2023

The popularity of reshoring electronics manufacturing services has boomed over the past few years due to the increased difficulty of electronics production by the global production leader, China. In lieu of China’s encouragement of offshoring, their production of both PCB assembly and manufacturing of semiconductors declined. The pandemic forced China’s government to implement strict ‘Zero-covid’ policies that effectively shut down many electronics production and assembly factories, resulting in Australian companies sourcing more of their electronics production and assembly domestically.

Much of 2023 saw an increased trend in domestically produced and handled electronic manufacturing services. In recent years, the Defence industry has had an increased demand for contract electronics from domestic suppliers due to advantageous delivery times, shipping costs, and better cyber-security measures. Many domestic suppliers within Australia recognise this and are continually increasing production and channels of services to meet their customer’s needs.

Current Challenges the Australian Electronics Industry is Facing

As a result of present trends, increased production costs are due to the rising costs of labour, materials, and inflation. This has led to an increase in the baseline pricing of electronic manufacturing services. The key to providing a middle ground for both service provider and customer is to increase efficiency and streamline the production and supply of the EMS.

Supply chain difficulties are also an ever-evolving challenge the industry faces, and the growing incentive of digitalisation has helped create efficient time-saving processes to combat these issues.

The challenge of promoting sustainability is also on the agenda. With global emissions of 4%, our industry has sought ways to reduce carbon footprints by implementing sustainable and socially responsible electronics manufacturing methods. The reduction in carbon emissions via digitalisation and increased Corporate social responsibility (CSR) in multiple manufacturing processes are some of the ways we at Hetech reduce our carbon footprint.

To find out more about how Hetech is addressing these problems and implementing solutions, contact us for more information.

In place of End of Financial Year gifts this year Hetech Pty Ltd has decided to support our Managing Director Mark Steiner in the annual CEO Sleepout.

Below are just some of the ways your donations can help those in need this winter:

$55 can help feed a family for a day

$120 can help keep a family warm this winter

$300 can help relocate a person sleeping rough to accommodation services

Every night, thousands of Australians experience homelessness. But it doesn’t have to be that way. This year I’m taking part in the Vinnies CEO Sleepout to raise money for the St Vincent de Paul Society to support Australians in need. For one night, I’ll be sleeping outside as part of an eye-opening experience to raise awareness and bring home the realities of homelessness.

To help break the devastating cycle of homelessness, I need your support. Will you help me to reach my target?

Almost all products consumers use day to day have some form of electronic component or system, and electronic manufacturing plays an integral part in the creation of these products. Electronic manufacturing for industrial designers involves the creation of components, products and systems, and their assembly into finished products. Without proper electronic manufacturing, the design of a product may not translate to a functional and reliable product.

Why Hetech?

Hetech partners with Industrial Designers, working with them on all parts of the manufacturing process from testing to production, Hetech has the experience and resources to ensure a product’s success.

Just some of the critical stages where Hetech can help in the electronic manufacturing process are:

- Design – Creation of the product design, including all electronic components.

- PCB Layout – The design of the printed circuit board is created based on electronic components.

- Fabrication – PCB is fabricated based on the design, and the electronic components are placed on the board.

- Assembly – Electronic components are soldered onto the PCB.

- Testing – The finished product is tested to ensure it functions correctly prior to mass production.

As a medium-sized manufacturer, Hetech can manufacture electronic products on both a smaller and larger scale. With experience in both commercial and niche markets, Hetech uses resources efficiently and is quickly able to adapt to changes in demand, all while ensuring quality control and delivering on time and within budget.

Hetech has been designing and manufacturing Printed Circuit Boards (PCB’s) for close to 30 years, our team is made up of experienced engineers and technicians with a multitude of experience.

Just some of the reasons our customers choose us to manufacture their PCB’s are:

- Experience: We have been in the electronic manufacturing industry for over 30 years, bringing a wealth of experience and knowledge in both the design and build of PCB’s.

- Quality: We are AS9100 and ISO9001-accredited, building to J-STD-001/IPC-A-610 class 3 standards and are a part of DISP (EL), providing for full traceability and more accurate processes for our customers. Due to our high level of quality control and accreditations, we have a reputation for delivering high-quality products. This is essential when it comes to PCB Manufacturing. Some of the printed circuit boards our team are responsible for manufacturing will be heading to space with our customer Gilmour Space.

- Customisation: We can customise PCBs to meet your specific requirements, our team of engineers can design, prototype, and manufacture PCBs that are unique to your business.

- Technology: We manufacture our PCBs using the latest available technology and equipment. This allows us to manufacture quickly and efficiently while ensuring the quality is not compromised.

- Customer service: We aim to exceed our customers’ expectations, from initial consultation to product delivery our team are with you every step of the way.

To view some of our work in this space head to our website.

Or, to contact us on how we can partner with you to optimise your product, please reach out to us via the button below.

We’ve been hearing a lot about Australian Space in the media lately, but what is involved in this complex sector and how is it helping us here on earth?

International Space exploration is working to develop advanced technologies that help everyday individuals here on earth, as outlined by NASA just some of these are:

1. Supporting water purification efforts worldwide

Joint collaborations between aid organizations and NASA technology show just how effectively space research can adapt to contribute answers to global problems. Using technology developed for the space station, at-risk areas can gain access to advanced water filtration and purification systems, making a life-saving difference in these communities.

2. Bringing space station ultrasound to the ends of the Earth

Medical care has become more accessible in remote regions by the use of small ultrasound units, telemedicine, and remote guidance techniques, just like those used for people living aboard the international space station.

3. Making inoperable tumours operable with a robotic arm

The same technology that went into developing neuroArm, the world’s first robot capable of performing surgery inside magnetic resonance machines, was born from the Canadarm, Canadarm2 and Dextre, the Canadian Space Agency’s family of space robots responsible for performing the heavy lifting and maintenance aboard the International Space Station.

4. Monitoring natural disasters from space

An imaging system used in space captures photographs of Earth from space for use in developing countries affected by natural disasters. Images from orbit can help with rapid response efforts to floods, fires, volcanic eruptions, deforestation, harmful algal blooms, and other types of natural events. Since the station passes over more than 90% of the Earth’s populated areas every 24 hours, it is available to provide imagery to developing nations quickly, collecting up to 1,000 images per day.

Plus, so much more, you can read more about this here:

Hetech has been providing electronic design and manufacturing services to this sector for some time now and, we look forward to further advances in technology thanks to the space sector.

Space Technologies

Space technologies and services benefit all Australians. Several of the daily conveniences we have come to expect, operate thanks to Space technology, just some of these are:

- Weather forecasting

- Agriculture

- Remote communications

- Internet access

- Online banking

- GPS, plus much more.

Hetech provides PCB manufacturing services to Gilmour Space

Gilmour Space has been in the news a lot recently due to the great work they are doing within the Australian Space sector. Founded by Adam and James Gilmour, Gilmour Space is the leading provider of Australian-made launch vehicles and satellite platforms.

Hetech has been manufacturing Gilmour-designed boards for their Remote Data Acquisition Units. The boards go into all stages of the 3-stage launch vehicle. They are used to sample sensor data from most of the subsystems on the rocket to do health monitoring through a Telemetry link back to the ground.

Recently, Mark dropped by Gilmour Space Headquarters and met with Gilmour’s Director and Head of Communications, Michelle Gilmour. We are excited about what is on the horizon, watch this space!

There are several exciting projects on the horizon for the Australian Space industry. To keep up to date with what Gilmour Space is doing in this space, simply head to their website.

What is a PCB?

Printed Circuit Boards (PCBs) are the backbone of all major electronics. You can find PCBs in nearly all computational electronics, from simple devices like digital clocks, and calculators to more advanced devices including computers, smartphones and cars.

A printed circuit board (PCB) is an electronic assembly that uses copper conductors to create electrical connections between components. A printed circuit board design must include a specific set of steps that aligns with the manufacturing process, integrated circuit packaging, and the structure of the bare circuit board.

In short, PCBs tell the electricity where to go, bringing your electronics to life.

What to do if you need a PCB in your product?

1. Specification: The first step in the design process is to develop a clear specification of your product. Our design team will work with you to create your specification. This is the most important step as it will ensure that both parties have a clear scope and outcome for the project.

2. Proof of Concept: Our engineers will then use off-the-shelf development kits to develop a “proof of concept”. This stage of the design will determine the types of technology used to achieve the goals of the product and whether the product concept is viable within the given budget and time frame.

3. Schematic Capture & Design: The proof of concept will then be captured as a schematic design. It shows all the components required and how they are connected.

4. PCB Component Placement and Routing: Using PCB design software such as Altium, all the required components on the functional schematic design will be placed on a digital PCB board.

5. Design for Manufacture: Hetech will always ensure that your product is designed to conform to modern manufacturing practices. As an in-house Design and Manufacturing company, we have access to valuable direct manufacturing feedback. This will assist in reducing your manufacturing overheads.

6. Final Delivery: After extensive testing and revisions and all parties are happy, we have a final product!