Your Mining Electronics Design & Manufacturing Partner.

Hetech has significant experience supplying high-quality Australian electronics manufacturing & design solutions to the mining industry, including clients such as CSIRO, FLSmidth & WEIR Minerals.

We will partner with you to develop an end-to-end turnkey solution to take your mining product to market.

Why is Mining Technology Important to Your Business?

Reduce Overheads

Use Industrie 4.0, IoT and big data to make crucial decisions, such as reducing time spent searching for minerals.

Improve

Safety

Why risk the safety of your employees in dangerous areas of mine sites, when you can send an automated machine?

Increase Efficiency

Use automation to reduce the manual labour involved in tasks such as adjusting spiral ores or sorting.

Our Core Services

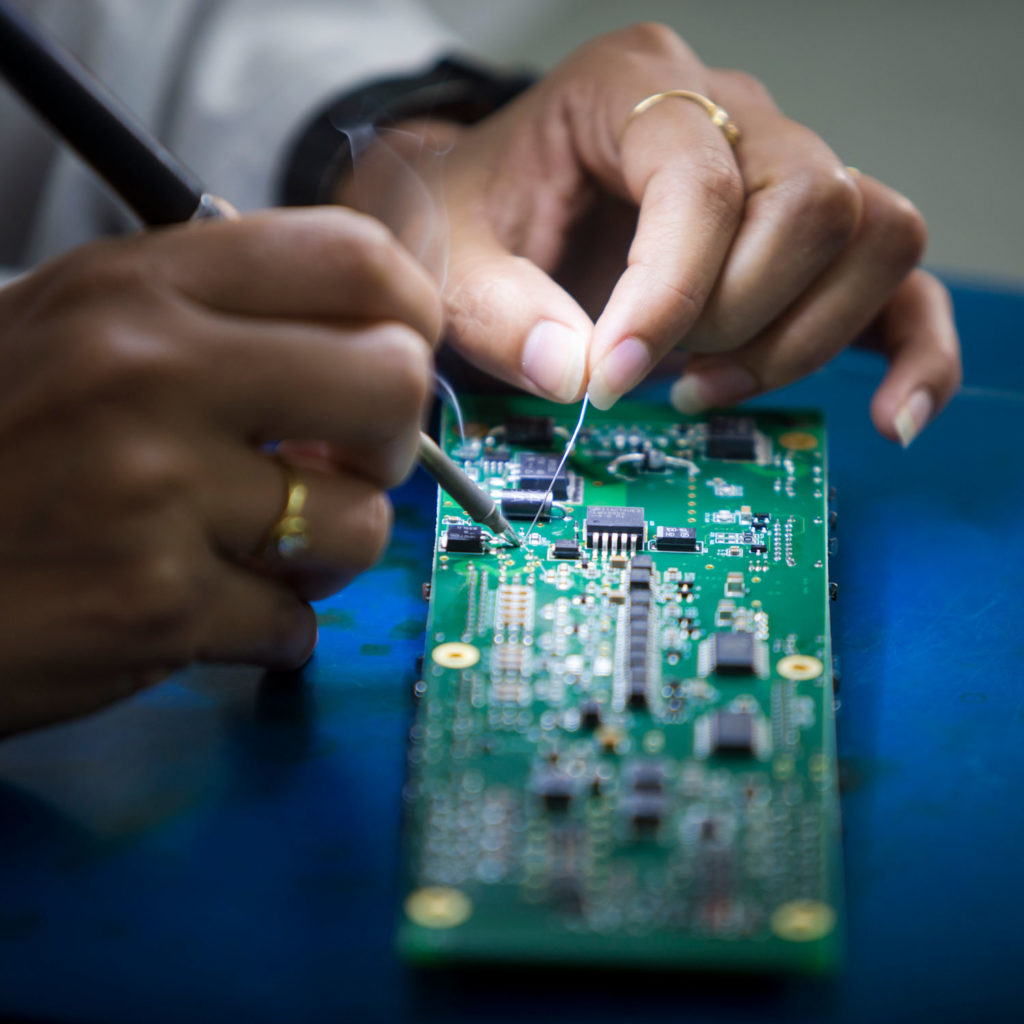

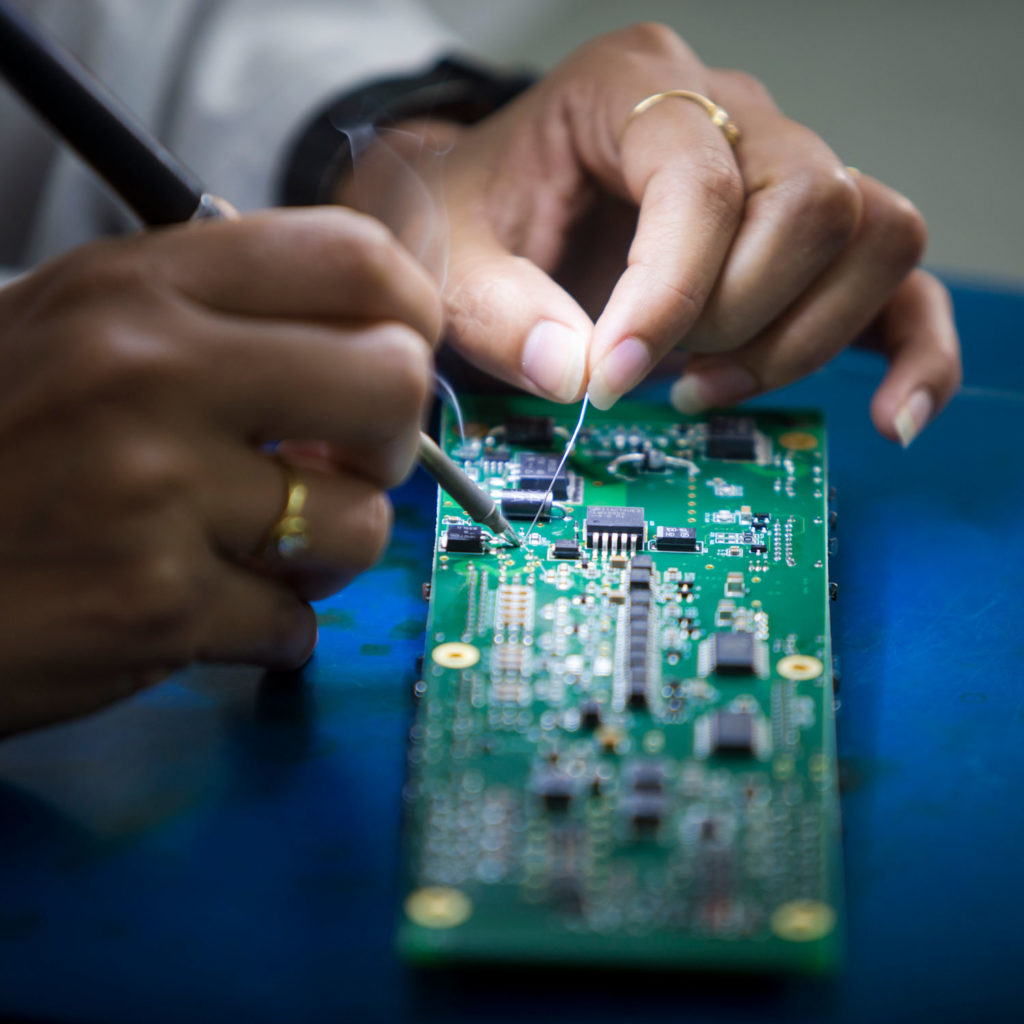

Contract Manufacturing

Turnkey Development

PCB Assembly

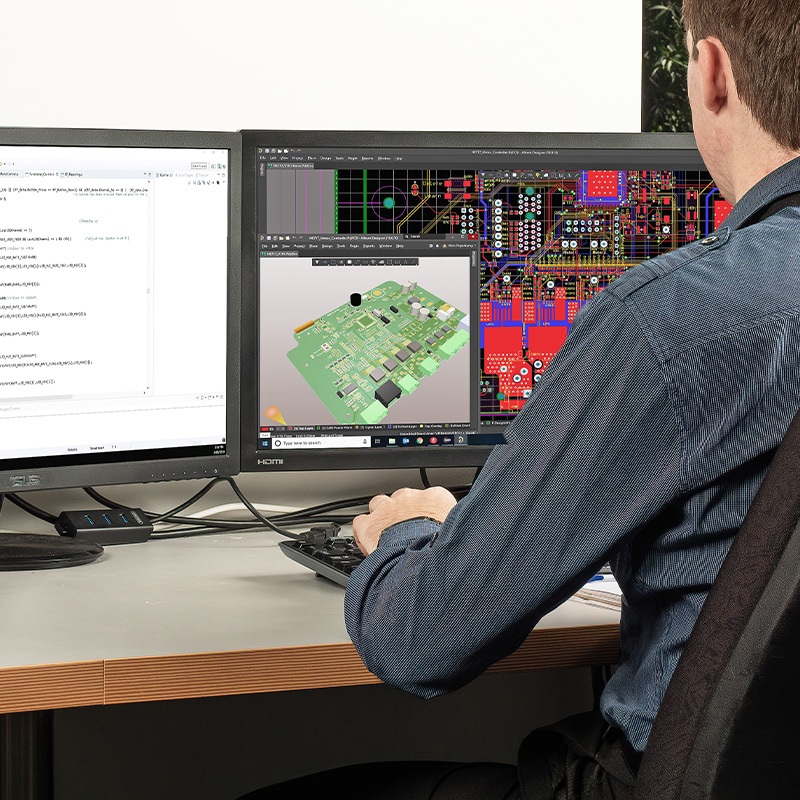

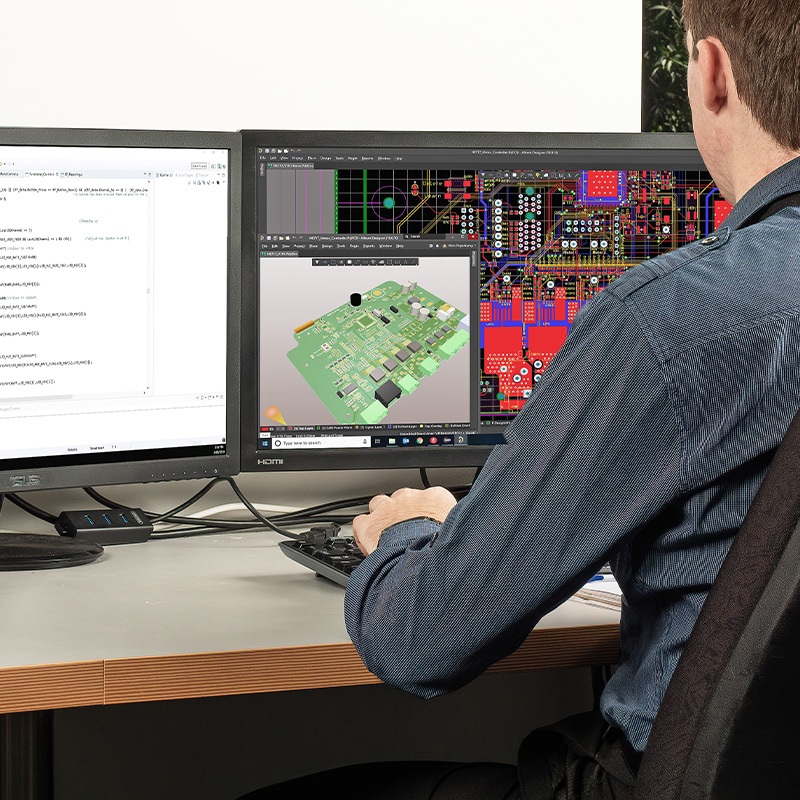

Electronics Design

We ensure your new product is Designed for Manufacture, cost-effective & functional.

Our Mining Customers & Projects

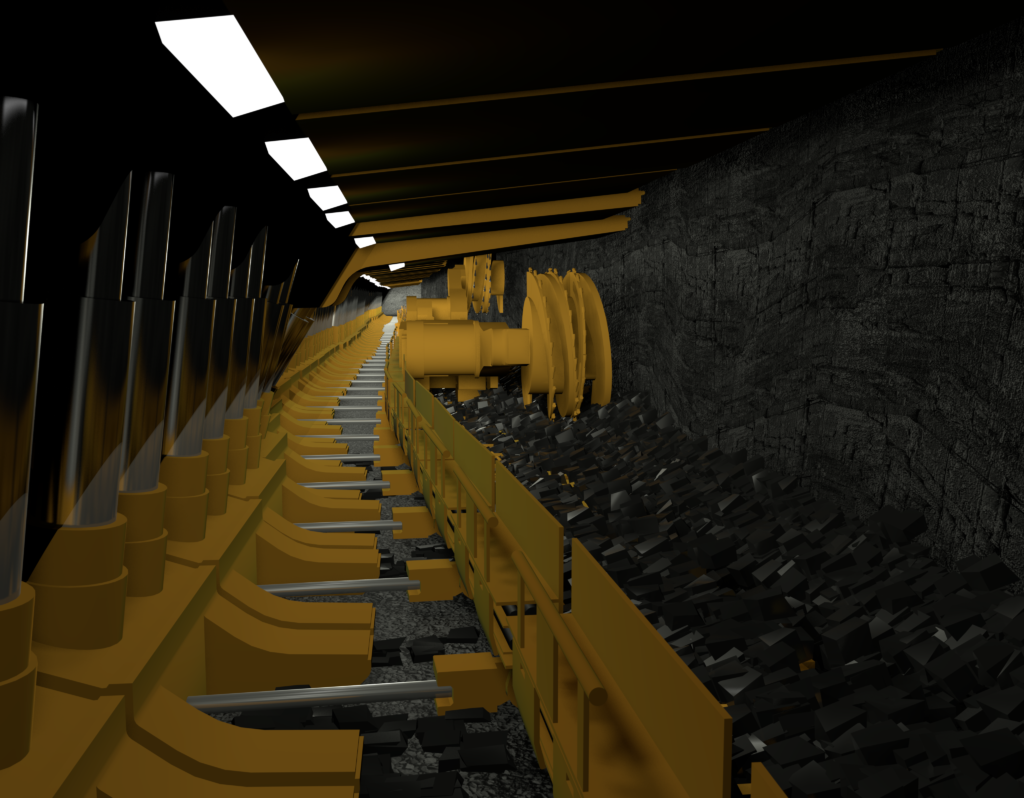

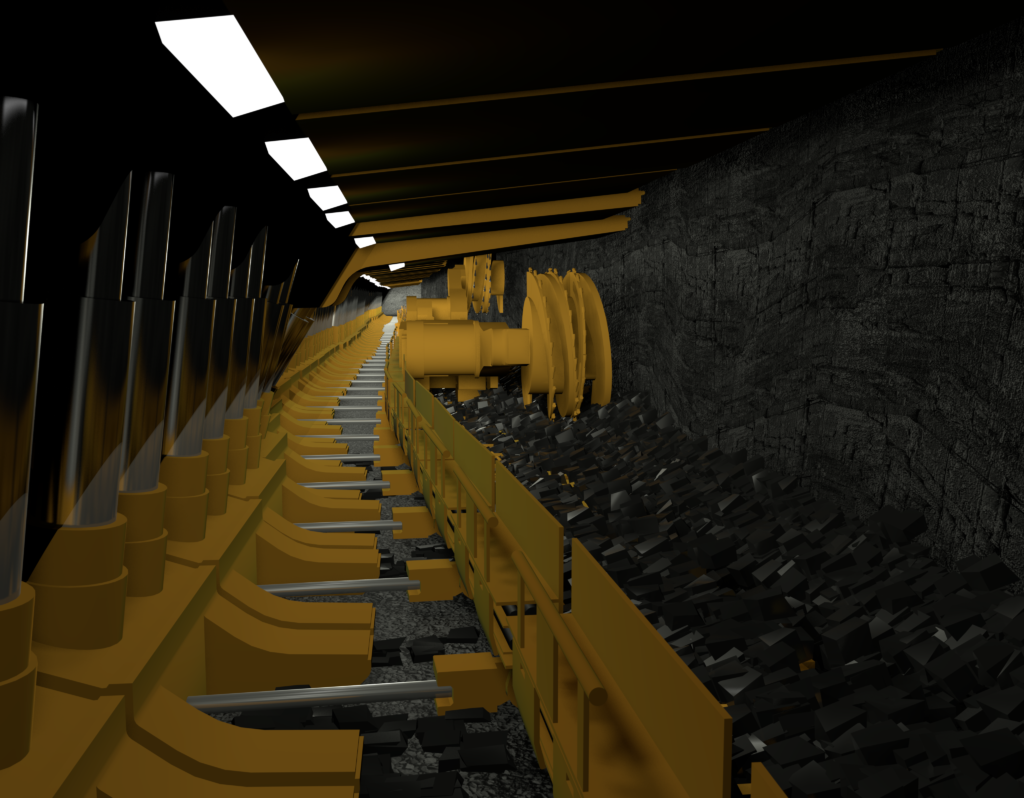

Longwall Automation

CSIRO, in partnership with the coal mining industry, has created an underground automation system which isolates people from mining hazards. It uses remote guidance technology to steer the longwall equipment by plotting its position in 3D, removing the need for workers to stop and correct the position of the equipment manually.

Requirement

CSIRO chose Hetech to build the boards which recalibrate and align the roof supports as the longwall machine moves down the tunnel.

Work Performed

Hetech has been successfully manufacturing the longwall boards for CSIRO thanks to its local support and ability to consistently build boards to the high standards (ISO:9001 & Class 3) required for mining.

Ultrasonic ShafTest Controller

The ShafTest is a portable Ultrasonic (UT) flaw detection system designed specifically to improve current UT techniques for monitoring the condition of shafts and pins in the mining industry.

Requirement

Bureau Veritas approached Hetech with an existing product design that required a significant redesign and update to perform to the high standard required for the project.

Work Performed

Hetech redesigned, updated and manufactured the new ShaftTest product. After the redesign process, Hetech implemented the required features on time, manufactured the product and assisted Bureau Veritas with after-sales support.

Spiral Automation

The manual nature of the product/reject splitters mean that operators are slow to respond to changes in feed quality.

Vanadium developed an innovative means of automating spiral splitters. This technology (patent pending) now allows for the accurate remote adjustment of each spiral’s product and middlings splitters.

Requirement

To design and manufacture an automation system that integrates into existing mining spiral circuits which will autonomously operate the feed splitters using linear actuators and motor controllers.

Work Performed

Hetech has designed and manufactured several units with fast manufacturing and delivery times to meet the specified requirements. The Spiral Galaxy system is now being utilised in Australian mines. Improving feed quality and efficiency through minimisation of human intervention, risk reduction and improved plant recovery.

“We partnered with Hetech’s engineering team to design and build a mining automation system to be integrated into gravity-fed spiral circuits. Their customer service and professionalism have exceeded my expectations. They consistently deliver within time-frames and even fly out engineers to assist with diagnosing and maintaining products in the field, ensuring the system was operating as expected. I highly recommend Hetech; they have gone beyond their expectations to ensure the best product possible.”

Gerald Van Niekerk, Director – Vanadium Group

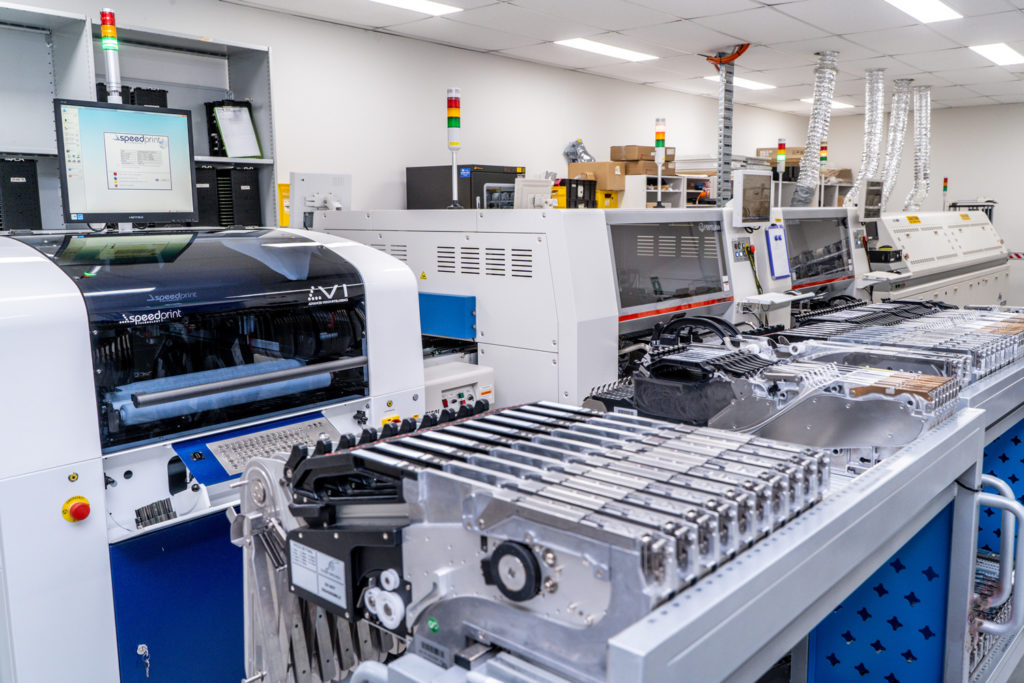

Our Facility

Capabilities

- Contract Manufacturing

- PCB Assembly

- Electronics design & engineering

- In-house class 1,2 & 3 manufacturing

- Full turnkey services

- Obsolescence management

- Build-to-print manufacturing

- Fast prototyping services

- Box building services

- Harness and cabling solutions

- Industrial design

- Compliance testing

- Conformal coating & Encapsulation

- Test-Jig manufacturing & design

- Automated Optical Inspection

- Surface Mount Technology (SMT) manufacturing

- Environmental testing chamber

Why Hetech

- Australian design and manufacturing services for close to 30 years.

- Rapid complete turn-key solutions

- Facilitating the transfer of technology and IP

- Delivering cost-effective support through working with prime contractors & OEMs

- High-quality IT infrastructure & security for ultimate data

- ISO9001 certification ensures the highest standard of manufacturing quality and processes.

- J-STD-001/IPC-A-610 class 3 manufacturing standards