Your Defence Electronics Design & Manufacturing Partner.

Hetech has significant experience supplying high-quality electronics manufacturing solutions to the defence industry, including clients such as Boeing Defence Australia, Saab Defence Australia and EOS.

Core Services We Provide for Defence

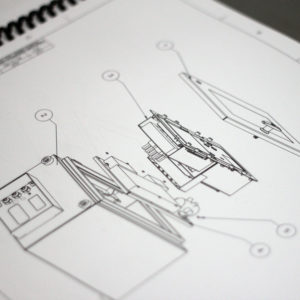

Build-to-Print

Box-Build & Sub-Assembly

Our Defence Customers & Projects

Project Currawong – Battlespace Communications System (LAND2072/2B)

Requirement

To deliver part of the battlespace communication system within a tight and dynamic time frame. Building both prototype and production units.

Work Performed

Manufacture of two sub-systems for the Network Access Module part of the project. This is a turnkey box build and we have delivered about 350 systems so far.

“Hetech’s electronics manufacturing and project management capabilities have been and continue to be integral to the success of project Currawong. Hetech have consistently manufactured and supplied hundreds of complex ruggedised hardware modules for delivery to the Australian Army. Hetech’s passion, honesty and integrity has been one of the key drivers in assisting the Currawong Project meet challenging delivery milestones. In the spirit of fostering true collaboration and transparency in business combined with an innovative and proactive engineering regime, Hetech have assisted in ensuring Project Currawong success to date, ahead of schedule and on budget.”

Mark Beggs, Field Hardware and Assembly (FH&A) Manager – Project Currawong

Collins Class Submarine – Integrated Ships Control Management Monitoring System (ISCMMS)

Requirement

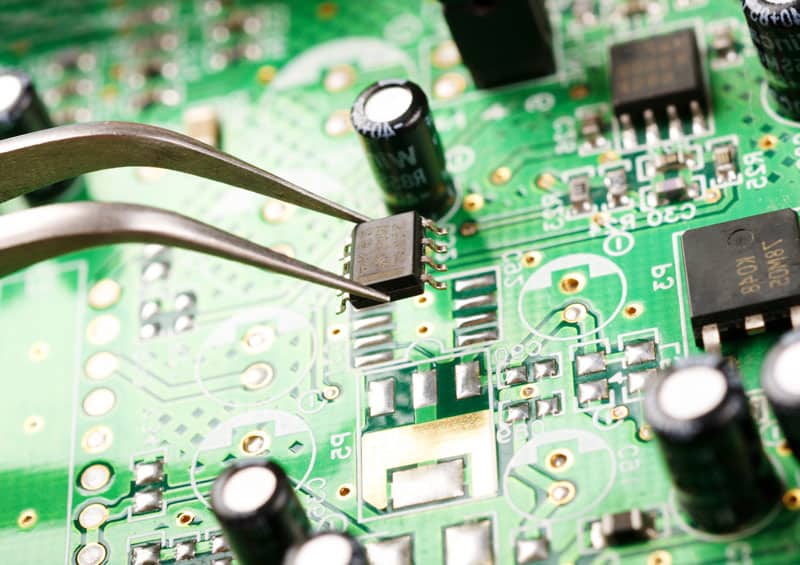

Redesign and manufacture electronic printed circuit boards which have become obsolete.

Work Performed

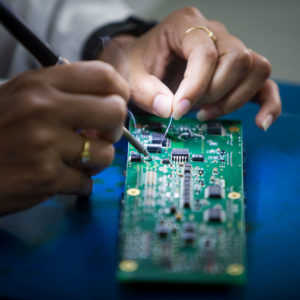

Hetech builds several PCBA’s for SAAB, as part of the sustainment of the Collins Class submarine.

“Hetech are a key supplier for our project working in partnership with us to achieve solutions to complex problems. Hetech’s expertise in electronic design provides us with confidence that the end product meets the strict standards and functionality that we require.”

Rodney McDonald, Procurement Manager – Submarine | Defence Operations

EOS – Remote Weapons System

Requirement

To build and supply part of the Remote Weapons System in large quantities, which is then integrated into various vehicle platforms.

Work Performed

Manufacture of approximately 7000 PCBs for EOS which go into their Remote Weapons Station. This RWS has also been approved by Rheinmetall for the Land 400 Boxer.T

“EOS Defence Systems has been working with HETECH for several years now. They are an invaluable and critical partner to our supply chain for PCBA’s. They have consistently delivered on time and on budget and to exceptional class 3 quality standards. We have very good relationships across all facets of their team and our communication is excellent, which is a key driver to the continued success between us. Thank you HETECH and keep up the great work.”

Kavita Gahlawat, Materials Manager

Capabilities

- Electronics manufacturing

- Electronics design & engineering

- In-house class 1,2 & 3 manufacturing

- Full turn-key services

- Obsolescence management

- Build-to-print manufacturing

- Fast prototyping services

- Box building services

- Harness and cabling solutions

- Sub-system integration for defence

- Industrial design

- Compliance testing

- Conformal coating & Encapsulation

- Test-Jig manufacturing & design

- Automated Optical Inspection

- Surface Mount Technology (SMT) manufacturing

- Environmental testing chamber

Discriminators

- Australian design and manufacturing services for close to 30 years.

- Rapid complete turn-key solutions

- AIC management & implementation

- Facilitating the transfer of technology and IP

- Delivering cost-e ective support through working with prime contractors & OEMs

- High quality IT infrastructure & security for ultimate data

- protection against cyber attacks and seamless

- communication with customers

- ISO9001 certification ensures the highest standard of manufacturing quality and processes.

Quality Assurance

Quality Assurance (QA) is paramount for industries such as defence and mining, which is why we are committed to continually improving our manufacturing QA processes, ensuring that we are always providing the best services and highest quality products for all our clients

Hetech is compliant to:

- ISO9001:2015

- Environmental IPC Standards

- IPC-A-610/Class 3

- J-STD-001

- C – Tick/RCM

Awards & Memberships

Hetech is a member of AIDN QLD. AIDN QLD is focused on assisting QLD SMEs to gain greater access to information, resources and key decision-makers in the public and private sectors of the Australian and international Defence industries.