News & Events | Page 5 of 8 | Hetech

It was great to sponsor the Australian Industry & Defence Network (AIDN National) Gala Dinner again this year. At Hetech, we are passionate about supporting our local network and the next generation of innovators.

Congratulations to all the finalists of the National Young Achiever Award and Jason Brand who won the award for his Flight Design.

With the east coast state borders now open, we are looking forward to getting back on the road to see our customers and colleagues.

Free for a coffee and chat?

Both Mark and Steve are on the road over the coming months. If you are interested, please contact Mark or Steve to arrange a chat.

Have you seen our LinkedIn page or the Hetech website ecently? We’re interested to know if you find our articles interesting, or is there something you would like to see more of?

Fill out our quick survey and tell us what you think

At Hetech we have been committed to quality electronics manufacturing & PCB assembly for over 30 years, producing and manufacturing locally here in Australia. Hetech is capable of manufacturing any project size from prototypes to high-volume runs. One of the recent projects we have worked on is the tailing dam systems.

Did you see Mark’s Q&A with Zachary Skidmore at Mining Technology? If not, don’t worry we’ve included the full article below!

The application of advanced sensory systems has proliferated across mine sites over the last decade to alleviate the threats posed by tailing dam failures. Zachary Skidmore speaks to Mark Steiner, managing director of Hetech about its new sensory system.

Tailings facilities pose a real and inherent threat to mining operations across the globe. The legacy of disasters such as the 2019 Brumadinho dam collapse, which led to extensive ecological damage and the deaths of 270, has led miners to focus more on the monitoring of these sites to prevent further disasters.

Hetech is an Australian technology company which has developed a new sensory system to detect and measure a vast range of unique local risks. From soil disruption that could reveal damage to dams, to slower and more subtle movements, the technology aims to help detect potential problems within the tailings facility and allow time for mine operators to correct the issue prior to a catastrophic failure.

We speak to its managing director, Mark Steiner about the potential of Hetech’s AIM system and its application in the evolution and monitoring of tailings facilities.

Zachary Skidmore (ZS) Could you provide an overview of Hetech’s AIM system?

Mark Steiner (MS): The early warning ground movement technology is designed to identify minute ground movements in three dimensional spaces and trigger real-time alarms based on site determined sensitivity.

It is made to provide early warning of events rather than long-term slow-moving changes, and is ideally suited to landslide detection, embankment failures, and catastrophic collapses of structures and ground surfaces.

ZS: How are the sensors deployed on the mine site? Are they static or used in conjunction with drone technology?

MS: The AIM system is designed as a fully rugged technology that can be remotely deployed in harsh and remote areas. Used in conjunction with drone technology, the sensors are installed on the ground where they are attached to infrastructure, buried underground, or submerged, submitting data to an AIM Cloud application.

ZS: How has the digitalisation of mines supported the efficacy of evaluation and monitoring?

MS: The digitisation of the mines has made many processes more automated, meaning workers spend less time on surveying because they have access to instant, real-time data and feedback. Consequently, we’re seeing less costly machinery breakdowns and worker downtime.

ZS: How much more data can the AIM system derive from tailings dams in comparison with standard monitoring protocols? What impact does this have upon the safety of these facilities?

MS: The system measures a wide range of unique local risks, from fast soil movements that indicate a dam breakage to slower, more subtle movements that give early warning of potential problems. When compared to standard monitoring, it provides more accurate data on the movements of the dam. The safety benefits of this relate to risk mitigation. Mine sites can detect and circumvent a potential crisis before it occurs. It’s preventative maintenance.

ZS: How does Hetech’s AIM system differ from other AI driven monitoring programmes?

MS: The AIM system is currently in the data collection phase. Before AI can be introduced, it will take some time to collect enough data on the dam movements to identify patterns and notable activity. In time, we will have gathered sufficient data to enable us to build AI monitoring into the system, but we are not yet at that point.

ZS: How critical is ESG to Hetech corporate policy?

MS: Hetech is committed to helping to build a more sustainable, resilient future. We are preparing to introduce environmental, social, and governance metrics into our corporate policy and look forward to sharing details of our plan once developed.

Queensland tech company builds system for a greener future for mining – The Pick Online Magazine

A Queensland company has been commissioned to custom build state of the art motion sensors to detect ground disturbance and provide early warning of environmental disasters like tailings dam collapses. The new technology brings the internet of things (IoT) to major engineering structures and is part of a breakthrough monitoring system called EarthSub being developed by Automated Infrastructure Monitoring (AIM).

Hetech Managing Director Mark Steiner said Australia was leading the development of digital solutions that would be instrumental in preventing major tailings dam disasters like the Brumadinho Dam collapse, in Brazil, which claimed 270 lives and led to the introduction of new world standards for dam monitoring.

Earlier this year, communities affected by the disaster were awarded a $7bn compensation from Vale, one of the world’s biggest iron ore miners.

Miners are under unprecedented scrutiny when it comes to protecting lives and the environment,” Mr Steiner said.

“The world currently has its eyes on climate change and global warming technologies – and rightly so, but the industry also needs to maintain a strong focus on preventing other environmental disasters.

“Until now, the sensitivity of monitors has been a weak link in the evolution of sophisticated mine monitoring systems.

“Hetech has specially developed the new system of sensors for gold mine in New South Wales to detect and measure a big range of unique local risks – from fast soil movements that indicate a dam breakage, as well as slower, more subtle movements that give early warning of potential problems.

“This gives asset owners the ability to monitor their assets remotely, around the clock. By tracking subtle ground shifts, they have a very real opportunity to correct problems before they occur.

“Most companies are responsible and keen to do the right thing but much of the storage infrastructure is ageing and there are big challenges for monitoring facilities in remote locations and achieving compliance with new international safety standards.”

AIM Managing Director, Peter King said the system was a unique solution for remote, real-time monitoring of tailings dams and other ‘at risk’ structural assets to detect impending catastrophic failures.

Following the introduction of the new Australian system in NSW, it will be commercialised for other local miners as well as for the global market. The system is the result of two years of research and development and was commissioned by AIM, an Australian company leading the development of the Earthsub ground monitoring system.

See more from The Pick by clicking here

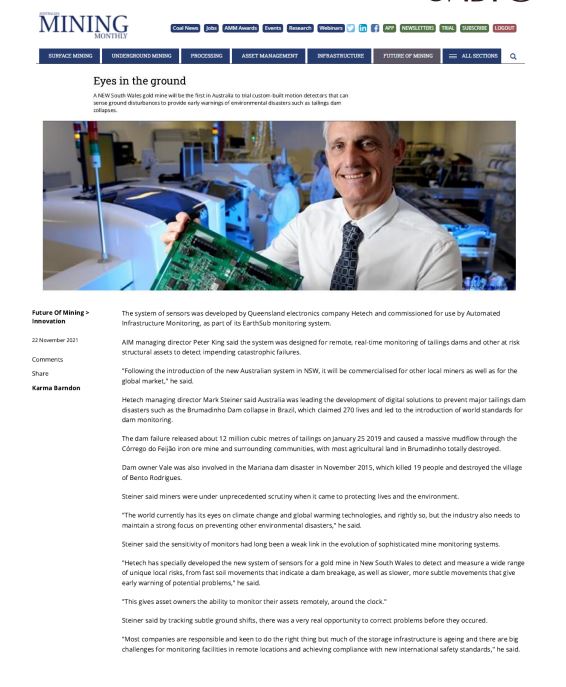

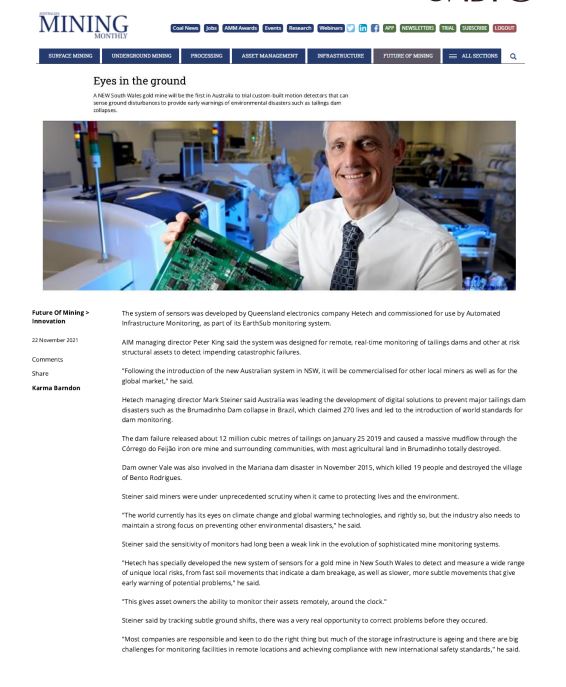

Hetech and the work we did in collaboration with AIM featured recently in Mining Monthly.

The custom build motion detectors built can sense ground disturbances to provide early warnings of environmental disasters such as tailing dam collapses. You can read the full article below or simply CLICK HERE.

Queensland tech company builds system for a greener future for mining

A Queensland company has been commissioned to custom build state of the art motion sensors to detect ground disturbance and provide early warning of environmental disasters like tailings dam collapses.

The new technology brings the internet of things (IoT) to major engineering structures and is part of a breakthrough monitoring system called EarthSub being developed by Automated Infrastructure Monitoring (AIM).

Hetech Managing Director Mark Steiner said Australia was leading the development of digital solutions that would be instrumental in preventing major tailings dam disasters like the Brumadinho Dam collapse, in Brazil, which claimed 270 lives and led to the introduction of new world standards for dam monitoring.

Earlier this year, communities affected by the disaster were awarded a $7bn compensation from Vale, one of the world’s biggest iron ore miners.

“Miners are under unprecedented scrutiny when it comes to protecting lives and the environment,” Mr Steiner said.

“The world currently has its eyes on climate change and global warming technologies – and rightly so, but the industry also needs to maintain a strong focus on preventing other environmental disasters.

“Until now, the sensitivity of monitors has been a weak link in the evolution of sophisticated mine monitoring systems.

“Hetech has specially developed the new system of sensors for gold mine in New South Wales to detect and measure a big range of unique local risks – from fast soil movements that indicate a dam breakage, as well as slower, more subtle movements that give early warning of potential problems.

“This gives asset owners the ability to monitor their assets remotely, around the clock. By tracking subtle ground shifts, they have a very real opportunity to correct problems before they occur.

“Most companies are responsible and keen to do the right thing but much of the storage infrastructure is ageing and there are big challenges for monitoring facilities in remote locations and achieving compliance with new international safety standards.”

AIM Managing Director Peter King said the system was a unique solution for remote, real-time monitoring of tailings dams and other ‘at risk’ structural assets to detect impending catastrophic failures.

Following the introduction of the new Australian system in NSW, it will be commercialised for other local miners as well as for the global market.

The system is the result of two years of research and development and was commissioned by AIM, an Australian company leading the development of the Earthsub ground monitoring system. If you need a bespoke electronic solution for a complex mining problem, you can find out more about Hetech at www.hetech.com.au

Over the last year, we have seen a shift in outsourced manufacturing to overseas countries be brought back to Australian shores. It is predicted that insourcing back to Australian shores will increase significantly over the coming years.

Made in Australia is making a comeback as businesses reverse the clock on years of offshoring jobs.

With supply chain issues and component shortages continuing to cause delays in manufacturing, there is a big push from businesses across Australia to have their products manufactured locally. Consumers are also driving the change, with Australians now eager to support local, Australian owned and operated businesses. More than three-quarters of consumers prefer to support Australian-made products, according to Roy Morgan data from 2019.

This trend has also been supported by an initiative by the federal government – which is now seeing a big increase in companies reshoring their production, research, design, logistics and distribution in Australia (The New Daily)

Hetech is Australian owned and run and has been designing and manufacturing products for over 30 years, supplying to a diverse range of industries and markets.

We have been working closely with our clients to navigate the impact of component shortages, including assisting them in planning ahead, keeping stock and placing standing orders. We too are planning ahead, with the prediction of insourcing to increase over the coming 5 years, we are expanding with a second manufacturing space, increasing our manufacturing capabilities by 60%.

To see more about our work and services, visit our website or contact us now!

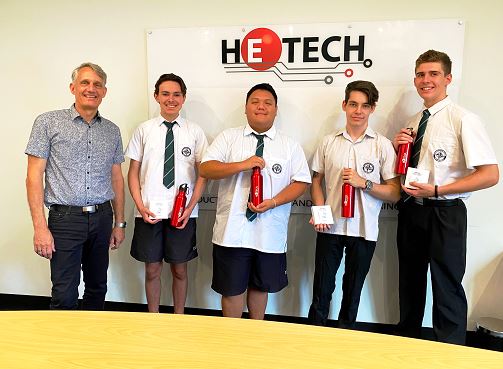

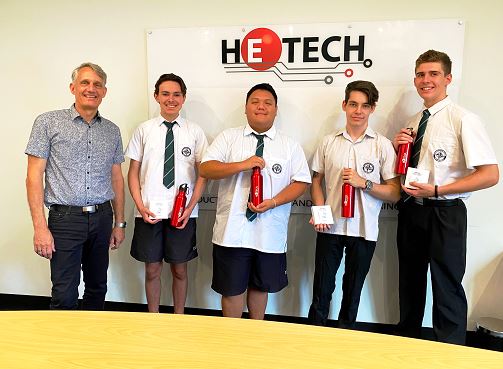

Hetech welcomed more Park Ridge school students to our head again office this week. A smaller group than the last visit, Mark got to spend some time explaining the world of electronics.

The students are part of the school’s specialist STEM program and planning their career options with a visit to Hetech to see firsthand how advanced manufacturing works.

It was an absolute pleasure to spend the afternoon with the students and show them around our state-of-the-art manufacturing facility.

It’s exciting to see more and more electronics students emerging in schools, all enthusiastic, and keen to learn about the exciting world of technology and the opportunities available to them.

As your electronics, design and manufacturing partner, Hetech is committed to supporting young people and the opportunities available to them in STEM fields, which increase young people’s choices and chances through science, technology, engineering, and mathematics.

Do you have a product idea that you’re wanting to get into production?

Have you ever wondered what information you’ll need when taking a new product idea to the design and manufacturer stage?

We’ve created a shortlist of just some of the questions you should be asking yourself to get your idea to the next stage of the lifecycle.

- Do you own the existing IP around the product?

- Will you retain the IP created in the Design Stage?

- Are there any third parties involved in the IP of this project?

- Are there any competitors on the market?

- What is the expected sales price of the product?

- Expected volumes? First-year / future?

- How does your product idea compare with existing products………pro’s and con’s?

- What distribution channels are there? Partners, etc

- How will the project be financed?

- What is the expected budget for the design?

Want to know more or need some help with your idea?

The Hetech team joined other SME’s, Defence Primes, Defence Force and industry organisations for the annual AIDN QLD Gala event for an evening of entertainment, networking, great food and wine.

On the night we heard from a range of keynote and guest speakers from the Defence industry, including Brigadier Mark Ascough and Ben James from NIOA.